GILSONITE IMPROVES PERFORMANCE WBM

GILSONITE IMPROVES PERFORMANCE WBM -GILSONITE PERFORMS IN WBM LIKE SULFONATED ASPHALT, AT SIGNIFICANTLY LESS COST

RAHA Gilsonite Company is proud to announce the launch of Gilsonite powder – a cost-effective, high-performance drilling fluid additive, effective in a wide range of water-based systems for both low and high-temperature wells.

Disperses quickly and easily in water-based muds

Gilsonite is a free-flowing powder that mixes easily through the hopper and disperses with only mild agitation. It is tolerant of contaminants and eliminates the need for additional surfactants or coupling agents.

GILSONITE IMPROVES PERFORMANCE WBM – Gilsonite has a wide range of performance benefits

- Mixes easily through the hopper

- Controls fluid loss and seepage

- Stabilizes shales

- Prevents lost circulation

- Strengthens the wellbore

- Minimizes differential sticking

- Maintains lubricity in tight formations

- Compatible with most water-based systems

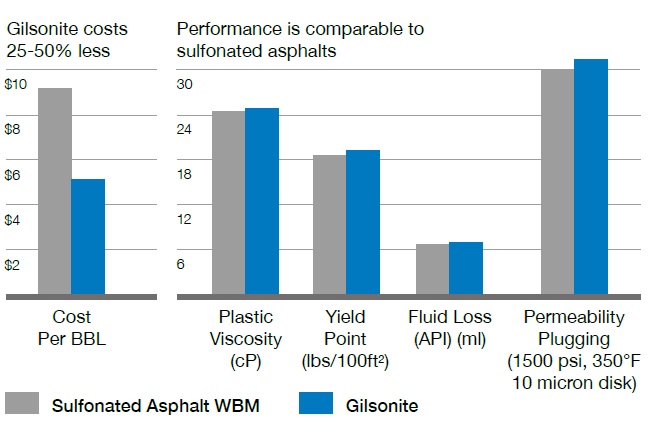

GILSONITE IMPROVES PERFORMANCE WBM – Get the performance of sulfonated asphalt and pay 25-50% less

Gilsonite performs comparably to sulfonated asphalt at a much lower cost. Plus, since it requires no additional surfactants or coupling agents, it further lowers costs by allowing you to use fewer additives. Also, Gilsonite is a cost-effective, high-performance additive effective in a wide range of water-based systems for both low and high-temperature wells. Gilsonite is renowned as an excellent shale stabilizer.

Water-Based Muds Applications:

Properties and features of Gilsonite

- Free-flowing powder resists clumping

- Compatible with most water-based systems

- Disperses with mild agitation

- A naturally occurring mined material

- Effective in both low and high-temperature wells

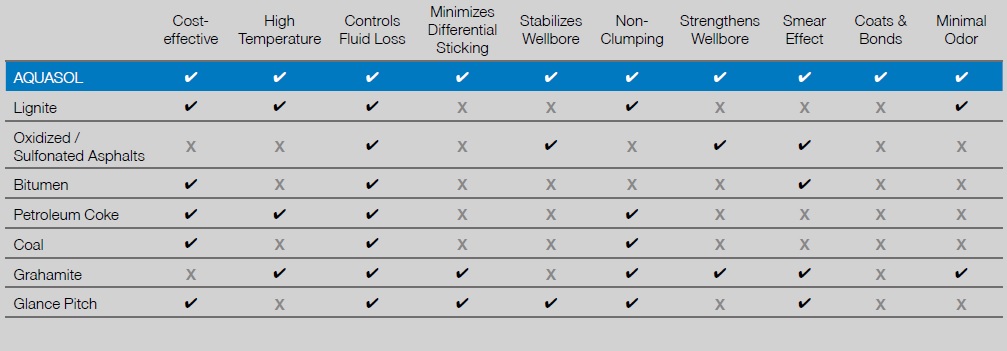

Gilsonite has overwhelming performance advantages over alternatives

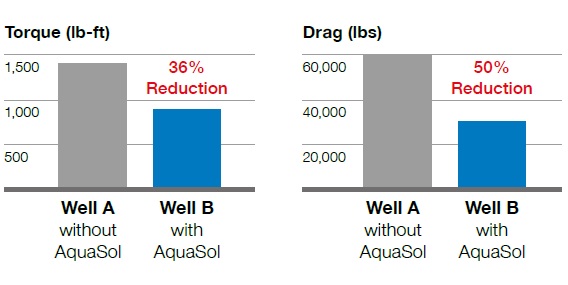

Proven to reduce torque and drag

In the South Pass area of offshore Louisiana, the operator wanted to reduce torque and drag. Wells in this area are normally deviated approximately 30° from vertical and are drilled with a conventional lignosulfonate mud.

- Well A: Conventional and bead-type lubricants were used for torque and drag reduction.

- Well B: 3-4 ppb of Gilsonite were added at approximately 10,600 feet.

Upon measurement, the torque on well B was reduced 36% and drag was reduced 50%. Caliper log comparisons from the two wells indicated substantial improvement.

Effective at controlling hole enlargement

Hole enlargement is a problem for wells drilled in the Eugene Island area of offshore Louisiana. On average, hole enlargement was approximately 50% in the 12.25-inch holes. Once 4 ppb of Gilsonite AquaSol were added to the conventional water-based formulation, hole enlargement was reduced to 15% in the same section.