Gilsonite usage in ink

General definition of Gilsonite powder in ink

Gilsonite and Gilsonite resin, derived by solvent extraction of raw Gilsonite, arc used as carbon black wetting agents for black news ink and heat set and gravure ink. In addition to wetting and dispersing the carbon black pigment, Gilsonite or Gilsonite resin binds the pigment to the paper. yielding the high-gloss print that resists rubbing off. Gilsonite can be mixed with other natural and synthetic oils. resins, and other additives to yield ink suitable for different types of printing presses and printing applications. Gilsonite typically comprises 2% to 5% of ink formulations. Refined Gilsonite resin is used in offset printing inks in concentrations of 15% or more to replace more expensive resins.

Gilsonite is readily soluble without heating in solvent especially in Xylene, Toluene, and Benzene and in the most chlorinated solvent. A non-petroleum base newspaper printing ink comprising a blend of Gilsonite flakes and tall oil fatty acids, together with carbon black pigment.

Gilsonite powder blending in newspaper offset printing inks as non-petroleum additive comprising a blend of Gilsonite flakes and tall oil fatty acid together with carbon black pigment. The proportions of the gilsonite powder and the tall oil fatty acid may be varied, as viscosity requirements change due to differences in press speeds, newsprint characteristics, and the like. The ink thus has readily adjustable viscosity, together with an enhanced flow and penetration characteristics, while being extremely economical to manufacture.

Gilsonite inks powder is readily soluble without heating in aromatic solvents (Benzene, Toluene, Xylene) and in most chlorinated solvents. It is also soluble without heating in aliphatic and low aromatic solvents (VM&P and other Naphthas, Ink Oils and Mineral Spirits), but mixing time is longer. Without heating, the pulverized grade is recommended.

Films developed from Gilsonite ink powder have a dark color with little bronzing effect. Solutions do not thicken upon aging. Gilsonite ink powder is compatible with drying oils, vegetable oils, resins, hydrocarbon resins, elastomers, asphalts, and waxes for specialty applications. It has limited solubility in most alcohols and ketones.

Printing Inks, Gilsonite is an important cost-effective ingredient in the manufacture of high-quality vehicles for dark printing inks.

RAHA GILSONITE Inks grade is a quick drying high gloss and corrosion resistant asphalt enamel. It is using for fully resistance to water, acids, alkalies, electrolysis and natural elements.

RAHA GILSONITE Resin competes advantageously with petroleum-based hydrocarbon resins, phenolic resins, and metal resinates, all of which it can complement or replace to various degrees. Various concentrations of RAHA Gilsonite Resin are used to manufacture law-rub-off news inks with superior gloss and tack properties.

How to make stabilized ink with Gilsonite powder

1– Carbon black in the range 10% to 27.8%.

2– Asphalt powder in the range 17.6% to 23.5%.

3– Tall oil fatty acid in the range 50.1% to 54.9%.

Gilsonite powder ink improve fluid of ink

It is known that asphalt powder, which is a natural product, is added to a varnish component for improving the printability of a printing ink such as dispersibility or fluidity. Gilsonite itself is black so that it is solely used for a carbon black containing inks. Gilsonite powder impairs the clearness of chromatic inks. Therefore, if Gilsonite is used for a chromatic ink, the amount thereof is limited to an extremely small amount. Under the above limitation, the effect of improving fluidity. is small, so that natural bitumen has not been practically used for chromatic inks.

Advantages of gilsonite in ink

Superior binding and carbon black dispersion make gilsonite the ideal inks additive.

The unique natural properties of Gilsonite make it the must-have, high-performance ink additive for top quality newspapers, magazines, and other publications.

Gilsonite in Inks industry is used basically as Carbon Black Dispersion Ink Additive considering the specifications of Gilsonite to be highly solvable in natural and synthetic oils. In Black Inks, Gilsonite Selects a better approach naturally to bond well with the paper and provides a more sustainable print.

When you read a newspaper or magazine, you touch the benefits of Gilsonite. The majority of the newspapers printed in the U.S., Europe, Japan and other locations throughout the world rely on Gilsonite to make the “no rub” ink their readers demand. The jet black in many heat set printed magazines and high-quality publications simply would not be possible without the excellent carbon black dispersion properties of Gilsonite.

Gilsonite delivers economic performance too. It is more cost-effective than hydrocarbon and phenolic resins. For premium performance, you can rely on Gilsonite to be Naturally Better.

- Superior binding properties for rub-resistant high-performance inks

- Unique properties make it an excellent agent for carbon black dispersion

- Cost-effective alternative ink additive to hydrocarbon resins, phenolic resins, and metal resinates.

Packing of gilsonite powder for ink

Gilsonite in lump form like rock packed in 500~1000 kg jumbo bag

Gilsonite powder 200 mesh packed in 500~1000 kg jumbo bag

Gilsonite powder 300 mesh packed in 500~1000 kg jumbo bag

Gilsonite powder 30-40 mesh packed in 500~1000 kg jumbo bag

Gilsonite powder 100 mesh packed in 500~1000 kg jumbo bag

Gilsonite powder 300 mesh packed in 25 kg pp bag

Gilsonite powder 200 mesh packed 25 kg multi-paper bag

Gilsonite powder 200 mesh packed 50 lbs multi-paper bag

Gilsonite powder 30-40 mesh packed pp bag on pallet

Bulk on vessel

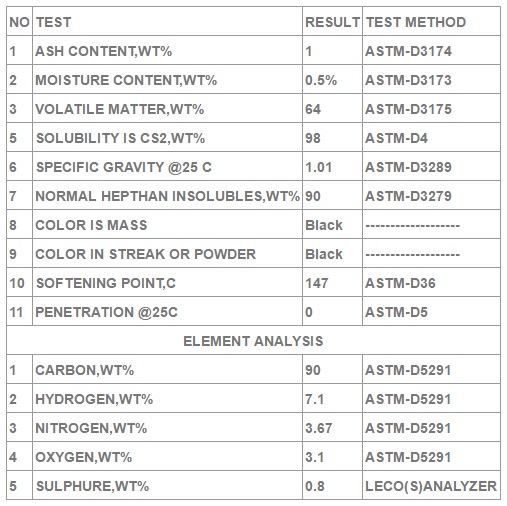

Analysis of Gilsonite powder for ink application

HEALTH & SAFETY

Gilsonite is a naturally occurring hydrocarbon. There is no known history of dermatitis, lung disease or other health problems associated with the handling of Gilsonite as supplied. Dust are subject to combustion. Normal precautions used with flammable materials apply.