Natural Asphalt

Natural Asphalt

RAHA Natural Asphalt, produced from bituminous rocks and it is a change after more than millions of years of natural mineral precipitation, under pressure and geological changes in the form of mining Having broken from the fine granular powder, light brown, where the asphalt content of about 80% to 85%, the rest are kind of limestone minerals. Quality rock asphalt can be used as a better modifier.

Natural Asphalt or Gilsonite is mainly used as an additive in asphalt and road paving, oil and gas drilling fluids, inks and paint manufacturing and also in the foundry sector.

Natural Asphalt is a well-known additive as a Hot Mixed Asphalt binder modifier; the unique properties of Natural Asphalt make a road that is less susceptible to temperatures and deformation performance issues. The Natural Asphalt-modified asphalt binder will produce a stronger road that can be thinner by nearly 20% compared with other pavements.

We offer a wide range of Mineral Bitumen grades for different industries. Our products are offered in different forms depending on your request. We produce Mineral Bitumen from mesh size 30 to 200. All types of our products are available in the forms of lumps, powder, and pellets. Our Gilsonite grades are selected depending on applications.

The dosage we recommend is to be 5-10% per ton mix, and the hot mix plant does not have to be modified.

It maintains the PG grading of the bitumen used and in some cases, it can enhance the low-temperature flexibility of bitumen while improving the cohesive strength of the bitumen and thereby reduces rutting and moisture sensitivity of the mix and in the final pavement.

The naturally occurring product has been proved to improve the adhesion between the aggregate and the bitumen and thereby prolong the service life of the road and reduce the maintenance needed during its lifetime.

Natural Asphalt has been used in many projects worldwide such as in the mixture for resurfacing the A25 Autobahn in Germany. The main advantages of using Natural Asphalt over polymer additives in the project in Germany was;

-

- It is an environmentally friendly natural additive

- It is affordable and leaves a great saving on materials

- It offers the elasticity benefits as all polymers

- It improves compaction and reduces emissions

Since the previous financial crisis in Europe, manufacturers and contractors have shifted towards using alternative additives in the oil and gas, construction and printing industries. In 2014 alone we produced 700,000 tons of Natural Asphalt (Gilsonite) to our customers worldwide. Most of our customers use Natural Asphalt as the most reliable and efficient replacement to all polymeric additives.

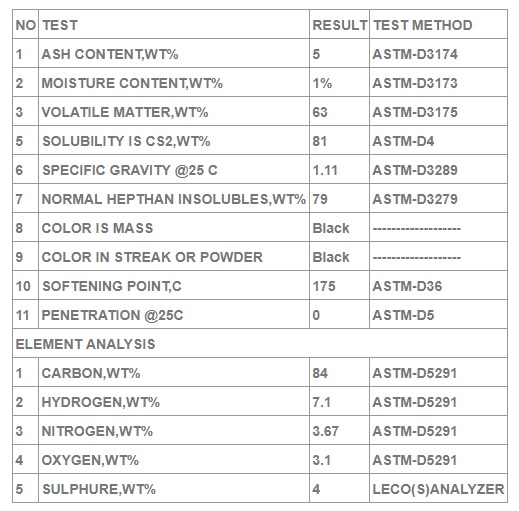

RAHA Natural Rock Asphalt Characteristics

The high softening point can significantly improve the high-temperature stability of asphalt pavement, improve the ability of pavement rutting. The nitrogen content of nitrogen element in the form of functional groups can increase the viscosity of bitumen, enhanced oxidation resistance, adhesion, and resistance make the cut off of the aggregate have been significantly improved, improved resistance to water damage ability asphalt pavement. Its molecular weight, when fused with the base asphalt at high temperature and small molecular, combined into a “semi- polymerization” effect.

It has very strong anti-microbial erosion on the surface protective film formed naturally tight light amount, more durable surface to improve the speed of slowing down the aging and prolong the service life of the road.

natural rock asphalt is wax-free, high wax can damage the quality of asphalt. Natural Rock Asphalt manufacturing process is simple, easy construction. by the modified base asphalt, Buton rocks make the more stable performance.

RAHA GILSONITE Co is the most reliable supplier of Natural Asphalt to the customers all around the world.

Natural asphalt

Natural Asphalt deposited in Gilane Gharb, Kuhdasht and Ilam -Iran has been known since the 1940s and it is the only natural asphalt deposits area in the Middle East. The deposits contain 80 to 97 % asphalt content and there is reserved between 200 to 250 million tons of natural asphalt. It has been used mainly for road construction and maintenance, however, oil well-drilling fluid to prevent lost circulation.

Mining natural Asphalt

Early exploitation and mining of natural asphalt occurred from 1940 to 1941 and produced 670 tons of natural rock asphalt in 1940, fluctuating during the years, and produced 8000 tons in 1945 with peak production was reached in 1949 mining 12,900 tons of natural rock asphalts. All asphalts were used for road construction.

Natural asphalt as drilling additive

For oil and gas drilling Mineral Bitumen is using as the variety of organic additives such as dispersing agents, retarders or fluid loss control additives. Gilsonite prevents interstitial water from filtering into the formation during cement placement, are generally polymer based. The Mineral Bitumen component appears to be particularly important to control fluid loss and to act as a shale inhibitor. This component working as an excellent shale stabilizer, bore hold lubricant, sealant for depleted sand, and wall cake conditioner.

Natural asphalt in road asphalt

The mixture of Gilsonite into asphalt relates to a base stock composition comprising a blend of Gilsonite and a rubber latex residue. The base stock may be used alone as a paving material or emulsified to form a natural asphalt emulsion having a variety of uses. The mixture of Gilsonite enforces asphalt against rutting and thickness of the asphalt with becoming thin.

- Have high bond capability due to resin effect to make the asphalt more water proof.

- Improve stability for heavy load traffic

- Have high melting point making the asphalt is more resistant to plastic deformation in tropical temperature.

- More resistant to ultra violet exposure and to fatigue due to repeated loads.

Natural asphalt in asphalt

The present invention is directed to an asphalt cement composition formed from petroleum asphalt, Mineral Bitumen, reactive oil, and an elastomer. The elastomer has a gel content of up to about 95 percent by weight.

Natural asphalt mixture in asphalt

It has been discovered that asphalt cement can be toughened with Mineral Bitumen and thinned with a reactive oil. Reactive oil is an oil that contains a high content of unsaturated fatty acids. By using a reactive oil, the oil would cure or react after application of the asphalt cement to the highway, thereby allowing for a lower viscosity application by curing later to prevent rutting.

The preferred natural asphalt is asphaltite such as natural asphalt. Gilsonite preferably one having a melting or softening point near about 300° F. so that it is more easily softened and blended with the petroleum asphalt at such temperatures.

How to mix natural asphalt in asphalt:

An asphalt composition consisting essentially of

100 parts by weight of a petroleum asphalt

from about 1 to about 10 parts by weight of a natural asphalt

from about 1 to about 10 parts by weight of a thinning reactive oil comprising at least about a 60

percent unsaturated fatty acid content having from about 14 to 24 carbon atoms, and

from about 1 to about 10 parts by weight of an elastomer.

Packing of natural asphalt lump and powder micronized form

Natural Asphalt in lump form like rock packed in the 500~1000 kg jumbo bag

Natural Asphalt 200 mesh packed in the 500~1000 kg jumbo bag

300 mesh packed in 500~1000 kg jumbo bag

30-40 mesh packed in 500~1000 kg jumbo bag

100 mesh packed in 500~1000 kg jumbo bag

300 mesh packed in 25 kg pp bag

200 mesh packed 25 kg multi paper bag

200 mesh packed 50lbs multi paper bag

30-40 mesh packed pp bag on pallet

Bulk on vessel

Specification of natural rock asphalt