Gilsonite in Road Asphalt

Gilsonite in road asphalt

Gilsonite (Natural bitumen) are natural occurring hydrocarbon substances characterized by a high softening point (above 110° C) in the class known as asphaltite. They are mined much like other minerals and sold essentially in their native state. They are fully compatible with asphalt and have long been known as asphalt hardeners and reinforcing agents. Gilsonite is currently sold all over the world as a road bitumen modifier in the form of a dry bulk solid granular powder.

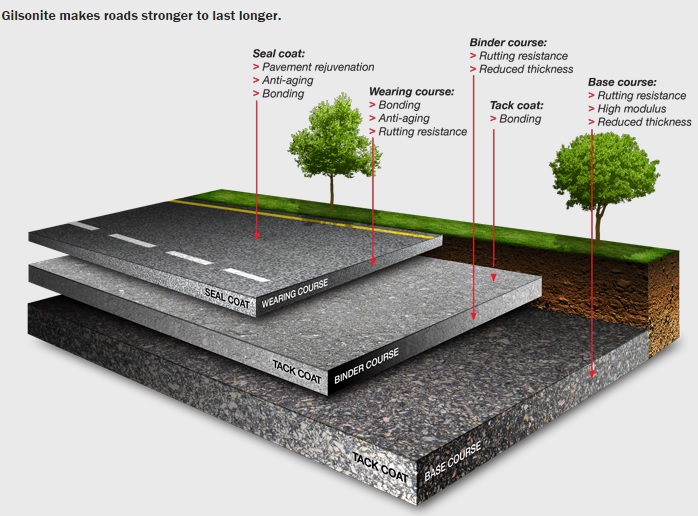

The mixture of Gilsonite (Natural bitumen) into road asphalt relates to a base stock composition comprising a blend of natural bitumen and a rubber latex residue. The base stock may be used alone as a paving material or emulsified to form a natural bitumen emulsion having a variety of uses. The mixture of natural bitumen enforces asphalt against rutting and thickness of the asphalt with becoming thin.

The present invention is directed to an asphalt cement composition formed from petroleum asphalt, natural bitumen, reactive oil, and an elastomer. The elastomer has a gel content of up to about 95 percent by weight.

Gilsonite (Natural bitumen) modified road has been particularly successful in highly stressed traffic areas. Natural bitumen, as the majority constituent, has been combined with virgin polymers such as styrene – butadiene – styrene (SBS) and Ethyl Vinyl Acetate (EVA). Gilsonite modified asphalt binders generally do not increase binder content requirement in pavement mixtures.

Performance grading of binders and pavement mixtures became a reality with the conclusion of the “FHWA” 50 million dollars, Strategic Highway Research Program, “SHRP”, in March of 1993. “SHRP” developed new binder specifications and test criteria based on the engineering properties related to pavement performance.

Nowadays the importance of asphalt, because of its use in road networks, airports, highways et cetera, is obvious to everyone all over the world.

Asphalt with an adequate quality is important in different aspects:

Economic: A considerable portion of Municipalities’ budgets, their Civic Engineering and Roads and Transport sections, are spent on manufacturing, applying and maintaining asphalt. If asphalt can be manufactured to have a two to three times longer effective lifetime the costs related to asphalt maintenance would be reduced commensurately. It is also obvious it would be more economical if cheaper substances could be used as modifiers or the bitumen for asphalt.

Environmental: The bitumen that exists in asphalt, due to containing heavy aromatic substances that can be released into the environment in small amounts after rainfall, pollute the environment, specifically underground waters. This pollution can be reduced by replacing a small percentage of the bitumen with green substances such as Gilsonite (Natural bitumen) or using complexing materials.

Driving: It is obvious that good asphalt affects driving. Nowadays, good quality asphalt with low deformation susceptibility, low-temperature susceptibility, high resistance to water stripping and high friction rate will help driving safety at high speeds and in different weather conditions (cold, warm, freezing).

Protecting and Saving Mineral and Natural Resources: Stone materials are used, alongside bitumen and other added substances, in manufacturing asphalt. By adding to the effective lifetime of asphalt the use of those materials would also be decreased.

To increase the rigidity and lifetime of asphalt, and to achieve the goals mentioned above, in advanced countries, different mixtures such as PPA, EVA, and SBS are used as modifiers and fillers. These materials are both expensive and toxic. And so producing a modified with lower manufacturing cost, lower toxicity, and equal or better quality is among the goals of asphalt scientists.

In Iran, for the last decade, asphalt modifiers have not been used due to their high prices. This has led to a dramatic drop in asphalt quality and effective lifetime so much as Iranian asphalt has a lifetime equal to one-third of American and European asphalt.

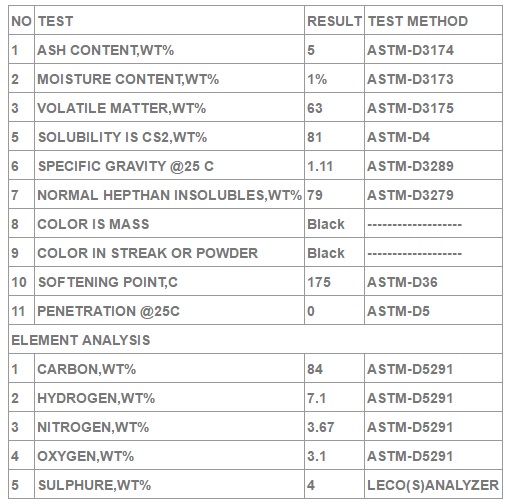

In this regard this cooperative, using micronized Gilsonite powder with a mesh size of 200 and solubility of more than 85% in carbon disulfide, has made efforts to modify asphalt to have higher rigidity and friction, and lower penetration rate, manufacturing cost, and toxicity.

We have used Gilsonite, as a powerful modifier, as both feeder and volumizer. Gilsonite is a byproduct of bitumen that can replace up to 15% refinery bitumen.

Goal: The produced powder is directly used in warm road bitumen, reducing the bitumen by 10-20. Micronized Gilsonite powder is used as a modifier in hot asphalt to add to its functionality, rigidity, stability and lifetime. Also, Gilsonite decreases penetration rate and increases viscosity, softening point, thermal resistance, resistance to deformation and resistance to water stripping. Also, this powder, due to having nitrogen-containing heterocyclic materials, adds friction between the road and the cars’ wheels, that, in turn, will increase the quality of driving in rain and while braking.

Lab results show that asphalt rigidity with 10% Gilsonite is 1357 kilograms while in absence of any Gilsonite it is 1097 kilograms. Asphalt modified with Gilsonite has more rigidity, resistance and effective lifetime than regular asphalt. In addition, it is cheaper and more environment-friendly and contains more bitumen.

Gilsonite mixture in road asphalt

It has been discovered that asphalt cement can be toughened with natural bitumen and thinned with a reactive oil. Reactive oil is an oil that contains a high content of unsaturated fatty acids. By using a reactive oil, the oil would cure or react after application of the asphalt cement to the highway, thereby allowing for a lower viscosity application by curing later to prevent rutting.

Gilsonite preferably one having a melting or softening point near about 300° F. so that it is more easily softened and blended with the petroleum asphalt at such temperatures.

An asphalt composition consisting essentially of;

- 100 parts by weight of a petroleum asphalt;

- from about 1 to about 10 parts by weight of a natural bitumen;

- from about 1 to about 10 parts by weight of a thinning reactive oil comprising at least about a 60

- percent unsaturated fatty acid content having from about 14 to 24 carbon atoms, and

- from about 1 to about 10 parts by weight of an elastomer.

Advantage of using Gilsonite in road asphalt

- Powdered Gilsonite is added to asphalt paving mixes to improve pavement performance. In the case of doing this project, the lifetime of asphalt in Iran will be doubled and tripled.

- With this method, the price of asphalt will be decreased by around 10%.

- No chemical polymer modifiers would be needed anymore to modify bitumen.

- 60% lower prices of all manufactured Polymer bitumen in comparison to its chemical and synthetic counterparts.

- There would no longer be the need to import chemical and synthetic polymer

- Increased thermal stability of bitumen (refinery bitumen will melt at temperatures above 70 degrees Celsius and crack at 0 degrees Celsius while this kind of polymer bitumen has a thermal tolerance range of –30 to +110 degrees Celsius).

- Decrease in bitumen’s penetration rate and increase in resistance to water stripping

Improves load-bearing capacity and reduces highway rutting and shoving. Increase in its Marshall load frame capacity. - Improves ductility and resistance to low-temperature cracking. Increase in bitumen’s softening point temperature.

- Improves the workability of the mixture during paving.

- Increase in bitumen’s Brookfield viscosity

- Increases the durability of the pavement;

- The decrease in the resulting bitumen’s toxicity in comparison to refinery bitumen and the synthetic.

- polymer kind due to the decrease in unsaturated materials.

- The possibility of production entirely based on domestic resources and technology.

- The asphalt modified with polymer bitumen has a higher PG and can be mixed, unlike other modifiers, with a low roller force with other asphalt mixtures.

- The resulting polymer bitumen is highly water repellent and tolerant against polar and acidic and alkaline dissolvents.

- Stronger and increases asphalt’s adhesion to aggregates.

- Natural bitumen functions by making the pavements harder.

Typically 5% to 15% Gilsonite is added to the mixture’s binder. It is generally regarded that Gilsonite reduces pavements’ low-temperature properties making them susceptible to thermal cracking. Natural bitumen (Gilsonite) melted into hot asphalt will reduce penetration and increase the viscosity of the binder. Gilsonite may also be mixed with aggregate prior to combining with the binder.

The features of this product, such as softening point, moisture, grain grading (mesh 200), ash percentage, ash texture, solubility in carbon disulfide, the percentage of aromatic carbons et cetera are controlled and optimized. The company has presented this product for sale after conducting numerous experiments and production in the cities of Kermanshah and Mehran in Iran and Erzurum in Turkey and under the supervision of these cities’ municipalities. And currently, this product (modifier for bitumen, asphalt and bitumen byproducts) is released for sale with consistently great quality and appropriate prices.

Packing of Natural Bitumen Lump and Powder Micronized form

Gilsonite in lump form like rock packed in the 500~1000 kg jumbo bag

Gilsonite 200 mesh packed in the 500~1000 kg jumbo bag

Gilsonite 300 mesh packed in the 500~1000 kg jumbo bag

Gilsonite 30-40 mesh packed in the 500~1000 kg jumbo bag

Gilsonite 100 mesh packed in the 500~1000 kg jumbo bag

Gilsonite 300 mesh packed in the 25 kg pp bag

Gilsonite 200 mesh packed 25 kg multi-paper bag

Gilsonite 200 mesh packed 50 lbs multi-paper bag

Gilsonite 30-40 mesh packed pp bag on pallet

Gilsonite Bulk on vessel

Analysis of natural rock bitumen