Gilsonite Solutions

Gilsonite Solutions

Gilsonite is an important component of today’s printing inks, paints & industrial coatings. Gilsonite is used as a hard resin and carbon black dispersant in a variety of coatings. Solutions of Gilsonite (sometimes called cutbacks or varnishes) are an excellent starting point for blending Gilsonite with other components of a final product formulation. Some formulators convert dry Gilsonite into liquid solution in their own facilities. Others will request a pre-made solution.

Converting dry, granular Gilsonite to a liquid solution also provides the opportunity to remove the small amount of abrasive grit that occurs in natural asphaltums. Stabilizing additives can also be added if a poor solvent is used or if high concentrations of Gilsonite are desired.

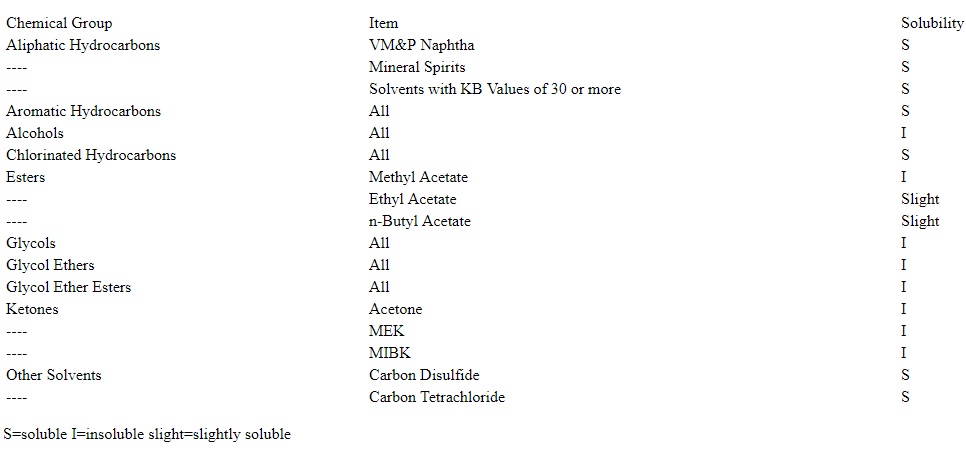

Gilsonite Solubility:

Gilsonite is readily soluble in aliphatic, aromatic and chlorinated hydrocarbon solvents. (Benzene, Toluene, Xylene) and in most chlorinated solvents. It has limited solubility in most ketones but is soluble in mixed aromatic solvents that contain a ketone component. Gilsonite is not soluble in water, alcohols, or acetone.

It also soluble without heating in Aliphatic and low aromatic solvents (VM&P and other Naphtha, Ink Oils and Mineral Spirits), but Mixing time is longer. Without heating, the pulverized grade is recommended.

It is more soluble in kerosene and naphtha than it is in crude oil. The effect of crude oil on set cement containing gilsonite is negligible beyond the dissolution of exposed gilsonite particles. Gilsonite has a melting point of 385°f. Some softening occurs above 24(‘f and particles may tend to fuse together. Because of the temperature reduction during circulation, Gilsonite can be used in wells having a static bottom-hole temperature of 300°f and slightly higher.

Solution Preparation:

Three basic procedures are used to dissolve Gilsonite. In each case, precautions for flammable materials should be used.

Cold-cutting:

Gilsonite is generally soluble in aliphatic and aromatic solvents at ambient temperatures. Some agitation should be used. The rate of the solution will depend on the type of solvent, the type and severity of mixing, and the grade of Gilsonite. The solution rate can be increased by using a high shear mixer, such as a Cowles disperser. When a ball mill or a paddle mixer is used, lump grade Gilsonite is recommended. When high energy mixing is available, either lump or pulverized grades may be used. Care must be taken to avoid “dry balls” of undissolved solid when using pulverized grades.

Hot-cutting:

The rate of Gilsonite solution can be increased by heating. Steam coils or hot oil is preferred. Direct-fired heating can be hazardous. Care must be taken to avoid or make up for vaporized solvent. Facilities for solvent containment are often necessary. The maximum processing temperature will depend on the boiling range of the solvent.

Hot fluxing:

Gilsonite can be hot fluxed into asphalts and high boiling oils. Once blended, the combination can then be let down with a solvent to reach the desired viscosity. This hot fluxing with another product can help overcome limitations of solubility. Selecting the correct blend or co-solvent can yield compatibility with a solvent that is normally of limited solubility.

Hot Fluxing Procedure:

Heat the oil to 200°F or more. Most of the high boiling, low aromatic ink oils in use today will require a temperature of at least 300-330°F. With good agitation, add dry Gilsonite at a rate that maintains constant dispersion of the particles until they dissolve. Be alert for foaming that can be caused by traces of moisture in the Gilsonite. Continue to agitate for 15 to 30 minutes beyond the point when the last of the Gilsonite particles is detected. The Gilsonite should now be completely dissolved and the solution ready for discharge.

Filtration:

The varnish must be filtered to remove the grit that is a natural component of Gilsonite. There are two common filtration methods. Each provides a different degree of cleanliness. Both methods are normally preceded by passing the hot varnish through a course wire screen (approx. 1/4“) to remove any large stones.

For a normal degree of cleanliness, the prescreened, hot varnish is passed through wire screen baskets of about 200 mesh (74 microns). Cloth bag filters can also be used, at a higher cost, when the company doesn’t have the personnel to clean the wire baskets. Disposal of the bags is also a consideration. Be careful to use bags that can tolerate elevated temperatures if hot cutting is performed.

For extra cleanliness, the prescreened, hot varnish is passed through cartridge filters of about 5 to 25 microns. These filters are also disposable.

Viscosity Modification:

Some Gilsonite solutions can be quite viscous at ambient temperature. Also, some solutions can steadily increase in viscosity over time. These characteristics are usually observed when using low aromatic oils with poor solvent power or when high percentages of Gilsonite are used. In these cases, small amounts of viscosity modifiers are often added to (1) keep the hot varnish sufficiently fluid for easy filtration and (2) to reduce and stabilize the ambient viscosity so the solution remains fluid until it is used.

The following is a partial list of modifiers that are effective at stabilizing the viscosity of Gilsonite solutions.

1. Soft asphalt flux. This is often substituted for 15 to 20 % of the Gilsonite in the varnish. At this level, it reduces the softening point of the Gilsonite by about 30°F. It should not be used when maximum hardness and rub resistance is desired, or when the fast solvent release is required, or when restrictive health safety regulations are in effect.

2. Tridecyl alcohol (TDA). More volatile than some modifiers (a flash point of 180°F), but effective. Generally used at 3-10%, based on the Gilsonite content.

3. Low molecular weight alcohols. Examples are n-propanol and n-butanol. These are effective, but their high volatility usually restricts their use to fast drying systems or products that are stored and used at ambient temperature.

4. Tall oil fatty acids. These are mainly oleic and linoleic acids with small amounts of rosin acids present. They are used for their high flash point and low volatility. In some cases, stearic or oleic acid, or vegetable oils such as linseed or soya bean oil, can be substituted for tall oil fatty acids with comparable performance.

5. Surfactants. A wide variety of commercial surfactants are also effective. Care must be taken to avoid any undesirable side effects on the performance of the final product.