Gilsonite Binder Grade

Gilsonite Binder Grade

Gilsonite vs. TLA in mastic asphalt mixtures

Gilsonite Binder Grade proven to offer superior performance and economic advantages The water-resistant characteristics of mastic asphalt are due to high concentrations of bitumen and other additives that help bind aggregate particles together. Trinidad Lake Asphalt (TLA) is the most widely used additive for mastic asphalt. Gilsonite is also employed as a bitumen additive and has been shown to provide superior performance characteristics when compared to TLA and other common additives. In 2017, ASPHALTA Prüf- und Forschungslaboratorium, an independent research facility located in Berlin, Germany, conducted comprehensive testing to determine how the physical and chemical properties of Gilsonite performed compared to TLA.

Executive summary:

The ASPHALTA study compared a typical mastic asphalt bitumen modified with 24.4% TLA and formulations of bitumen modified with Gilsonite Binder Grade at significantly lower concentrations of 5% and 6%. All of the formulations utilized a bitumen content of 8.2% in order to yield acceptable results in workability as well as deformation resistance. The study revealed that the Gilsonite samples:

- Increased the softening point of the asphalt mixture

- Improved the dynamic shear modulus (strength)

- Increased viscosity

- Showed lower static and dynamic indentation

- Exhibited higher breaking strength at lower temperatures

- Required a significantly smaller volume of additive material than TLA to achieve equal or superior results

- Replaced 100% of the binder while TLA replaced only 50% of the binder

Key performance and economic results

- The increased softening point and decreased penetration measurements suggested that the Gilsonite-modified asphalt would demonstrate greater resistance to rutting.

- Phase angle testing across the temperature range of –20º to 160ºC showed the Gilsonite-modified binders to be more elastic, indicating the likelihood of reduced cracking, especially in cold weather conditions.

- Lower static and dynamic indentation indicated a greater resistance to permanent deformation.

- The lower concentrations of Gilsonite required in the test samples also suggest that a dramatically smaller volume of additive material is required, resulting in less time and energy spent mixing and in significantly reduced material costs.

A challenge to tradition

Trinidad Lake Asphalt has been the primary additive for mastic asphalt, but a new study finds that Gilsonite Binder Grade offers clear performance and economic advantages.

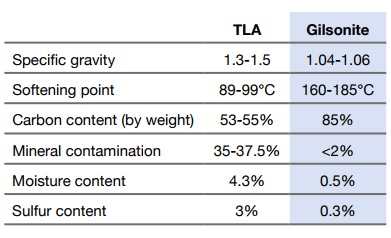

Trinidad Lake Asphalt and Gilsonite Binder Grade: What’s the difference?

Trinidad Lake Asphalt and Gilsonite are both naturally occurring materials that have been used to enhance the characteristics of asphalt pavement for more than 100 years. Trinidad Lake Asphalt is mined from the Pitch Lake at La Brea in southwest Trinidad. Gilsonite is mined in the Uintah Basin in Utah of the United States and Kermanshah- Iran.

A look at the physical and chemical properties of TLA and Gilsonite reveals substantial differences that play a role in performance as bitumen modifiers. Gilsonite has much lower mineral contamination and sulfur content than TLA.

Testing methodology and results

Bitumen formulations tested:

- The standard mastic asphalt formulation of PEN 30/45 plus 24.4% TLA

- PEN 30/45 plus 5% Gilsonite

- PEN 50/70 plus 6% Gilsonite

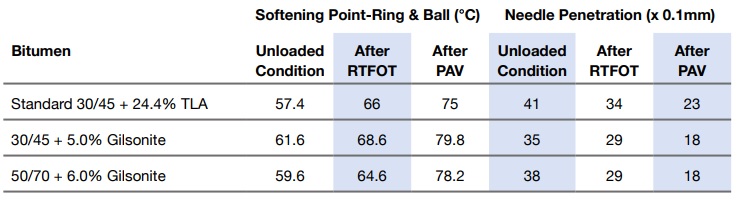

Softening point and needle penetration tests: Resistance to rutting

The softening points of the various mixtures were tested with the ring and ball method under three conditions to simulate mastic asphalt at different stages of the life-cycle: in unloaded (fresh) condition; after a rolling thin film oven test (RTFOT) to simulate moderate aging; and after a pressure aging vessel (PAV) test to approximate long-term aging.

Needle penetration tests were conducted under the same conditions.

These tests showed that both the 30/45 bitumen modified with 5% Gilsonite and the 50/70 bitumen modified with 6% Gilsonite increased the softening point and decreased the penetration over the standard formulation of 30/45 bitumen modified with 24.4% TLA.

The higher the softening point of an asphalt mixture, the more it will resist deformation and rutting which occur at higher temperatures. The lower the needle penetration number, the less the likelihood of moisture penetrating the surface of the asphalt.

A measurable difference

in performance, Decidedly different physical and chemical properties are key to the increased performance of Gilsonite as a bitumen additive.

A lower softening point increases the likelihood that asphalt will deform and rut.

Gilsonite Binder Grade increased the softening point of the asphalt mixture, enabling it to remain stable under higher temperature conditions.

Increasing shear modulus and viscosity

As a viscous material, the properties of asphalt will change as various forces are applied to it and as temperatures change. A higher shear modulus is always desirable, but the viscosity of a material will also be affected by temperature.

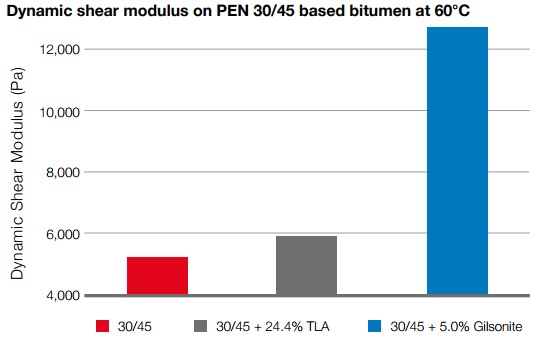

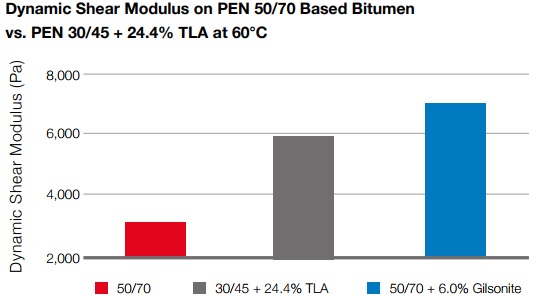

In the ASPHALTA study, the asphalt samples were tested with a dynamic shear rheometer to determine how the viscosity would change across a wide temperature range.

The most interesting results for the 30/45 bitumen were at 60°C, where the binder modified with 5% Gilsonite showed a viscosity more than double that of the binder modified with 24.4% TLA, using only one-fifth the amount of additive.

Similarly, at 60°C, the 50/70 bitumen modified with 6% Gilsonite showed a viscosity over 15% higher than the 30/45 bitumen with 24.4% TLA, using only one-fourth the amount of modifier.

Enhanced viscosity reduces rutting and fatigue

rutting and fatigue The sample modified with Gilsonite Binder grade increased the dynamic shear modulus across the entire temperature range.

Elasticity: Asphalt strength in motion

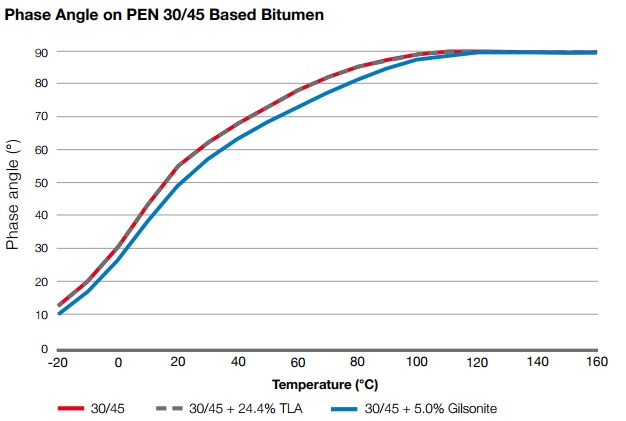

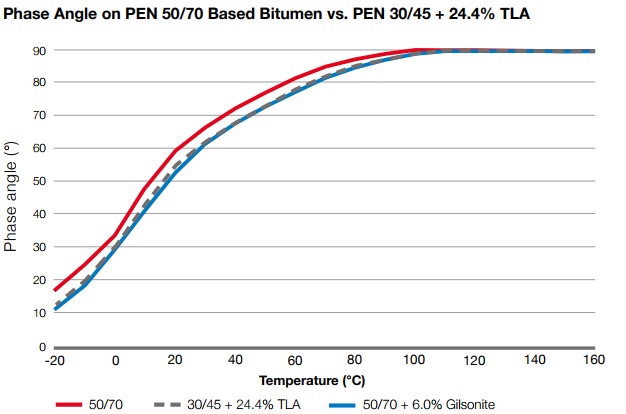

Elasticity is a good measure of asphalt’s ability to resist cracking by resuming its original shape following deformation.

A lower phase angle measurement indicates greater elasticity. The 30/45 bitumen modified with just 5% Gilsonite showed consistently lower phase angles (greater elasticity) at temperatures from –20º C to 120º C, than the standard 30/45 bitumen modified with almost five times as much TLA.

The 50/70 bitumen mixture with 6% Gilsonite equaled phase angle measurements of the 30/45 bitumen modified with 24.4% TLA at temperatures from –20º C to 120º C, using only one-fifth as many additives.

Greater elasticity decreased cracking with less additive

Asphalt mixtures with Gilsonite demonstrated consistently greater elasticity than the standard bitumen modified with 24.4% TLA. Elasticity allows asphalt to resist cracking.

Easier blending with a fraction of the material

Heating and blending asphalt, aggregate, bitumen and additives is a specialized, energy-intensive process requiring precise measurement and control. Reducing the time required to get a hot mix ready to pour will result in significant savings of energy, cost and effort.

The Gilsonite-modified mixtures tested provide several distinct advantages.

- Gilsonite binder grade is a much purer hydrocarbon than TLA, meaning there are fewer contaminants to deal with.

- The specific gravity of Gilsonite is lower than TLA (~1.05 vs. ~1.4), so it will disperse into the hot mix more evenly.

- Most notably, the Gilsonite additive produces equal or superior performance to TLA with only a small fraction of the amount of product. A formulation with 24.4% TLA uses five times the product as a mixture using 5% Gilsonite. With so much less product to add, a formulation with Gilsonite will require considerably less time and energy to blend, and reduce material costs.

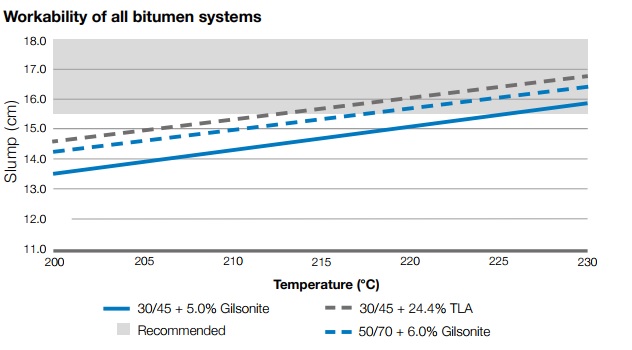

Hot mix workability

Since mastic asphalt is often applied by hand, achieving mixture workability at the lowest temperature is an important consideration.

To measure hot mix workability, a precisely measured sample of a mixture was spread on a Haegerman Table where heat was applied and the expansion of the mixture was measured as the temperature increased. The generally accepted standard of workability is an expansion of 15.5 cm (indicated by the shaded area in the chart).

Of the formulations tested, the mixture modified with TLA expanded to 15.5 cm at a temperature of 212ºC, and the 50/70 + 6% Gilsonite mixture reached 15.5 cm at 217°C – a difference of only 5ºC, achieved with only one-fourth the amount of additive.

Less material = less energy

required and lower costs A formulation with 24.4% TLA uses five times the additive as a mixture using 5% Gilsonite. Gilsonite will require less energy and time to blend.

Expansion vs. temperature

An ideal measure of hot mix workability is when the desired expansion is achieved at the lowest temperature. Gilsonite Binder Grade and TLA mixtures are within a few degrees of each other, but Gilsonite offers other advantages at the hot mix stage, including easier blending with the less additive material.

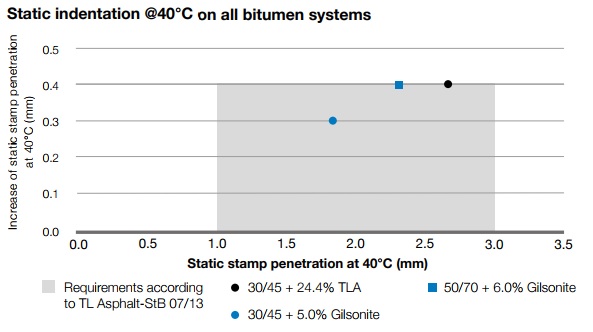

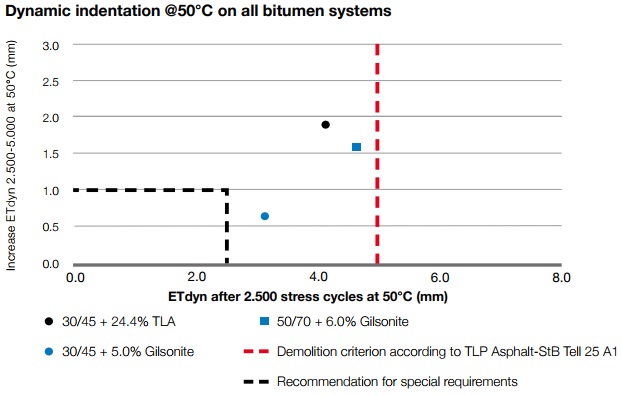

Indentation tests: Susceptibility to permanent deformation

Using precisely controlled applications of pressure, the ASPHALTA study determined how much each sample would be permanently indented.

Static indentation is the amount of penetration the test stamp will exhibit from an application of pressure measured at two 60-minute intervals at 40º C. The first result is shown on the x axis, the second on the y axis. Lower numbers on either axis indicate less penetration.

Dynamic indentation measures the penetration after numerous stampings at 50º C.

In both tests, both Gilsonite samples – using significantly less product – showed less indentation than the 24.4% TLA sample.

Resisting static and dynamic pressure – increasing performance at a lower cost

The addition of Gilsonite Binder Grade reduced a sample’s likelihood of permanent deformation.

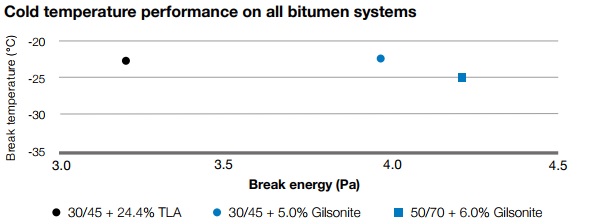

Cold Temperature Performance

The ability of asphalt pavement to withstand cold temperatures is one of the most important considerations.

This sophisticated test subjected the mastic asphalt samples to both cold temperature and pressure. As the asphalt mix is progressively cooled, a load is applied to it until it breaks. The test measures both the energy necessary to break the sample and the temperature at which it breaks.

Both the Gilsonite samples withstood lower temperatures and had substantially higher breaking strength than the asphalt modified with 24.4% TLA.

Conclusions

ASPHALTA’s comprehensive testing carefully compared bitumen formulations modified with 5% and 6% Gilsonite to the widely used 30/45 PEN bitumen modified with 24.4% TLA. Some clear conclusions can be drawn.

Compared to the TLA mixture, the samples modified with Gilsonite:

- Increased the softening point and viscosity, which will result in greater resistance to rutting.

- Increased elasticity, reducing the likelihood of roadway cracking.

- Showed lower static and dynamic indentation, indicating a greater resistance to permanent deformation.

- Demonstrated superior cold temperature performance, with both greater breaking strength and the ability to withstand colder temperatures.

- Used only one-fifth as much product, which would mean faster and simpler mixing, reduced costs of shipping and handling and, most importantly, greatly reduced material costs.

The findings of this respected research laboratory clearly demonstrate that Gilsonite modified binders can help make stronger, longer lasting roads using significantly less product, and that Gilsonite should be considered an advantageous alternative to the industry’s current mastic asphalt standard.

Greater strength, lower temperatures

The Gilsonite-modified samples withstood lower temperatures and had substantially higher breaking strength than the asphalt modified with 24.4% TLA. In both measures of cold temperature performance, Gilsonite was superior.

Stronger lasts longer, costs less

In practical use and research studies, Gilsonite has been proven to help make roads that are stronger and last longer than those made with other additives.

Compared to a 24.4% TLA mixture, a 5% Gilsonite mixture greatly reduces material use and costs.