Gilsonite

What is Gilsonite ???

A Safe, High-Performance, Cost-Effective Additive.

Some types of asphalt are made by nature as a result of the slow change of Crude oil and evaporation of its volatile materials during many years. Such an asphalt is called natural asphalt and survives more than oil asphalts. Such an asphalt may exist in nature as a pure element (asphalt of the lake) such as asphalt lake of Behbahan in Iran and Trinidad asphalt lake in America or be extracted from mines (mineral bitumen).

Gilsonite is the generic name of a mineral oil-based hydrocarbon group registered with CAS Number of 12002-43-6. In fact, when the crude oil in the depths of the earth loses the volatile substances over time and under atmospheric factors, a solid black material remains that is called natural bitumen. Gilsonite is also known as natural bitumen, mineral bitumen, natural asphalt, asphaltum, uintaite, hard asphalt, and zagronite, high purity, solid hydrocarbon rich in asphaltenes and nitrogen compounds. It is glossy black and brittle and contains little sulfur or ash. Although it appears similar to hard coal or asphalt, its chemical properties are significantly different. It is classified as an asphaltite. Due to its unique compatibility, Gilsonite is frequently used to harden softer petroleum products. Gilsonite is soluble in aromatic and aliphatic solvents, as well as petroleum asphalt. It is brittle and can be easily crushed into powder. In nature, Natural bitumen can be found as underground veins in either pastry or solid state with no crystalline structure and with a color ranging from black to blackish brown. The width of the veins ranges from 0.5 to 2 meters, reaching sometimes to 5.8 meters. The veins are nearly parallel to each other and are oriented in a northwest to southeast direction. They may extend many kilometers in length. The vein will show up on the surface as a thin outcropping and gradually widen as it goes deeper. Due to the narrow mining face, Gilsonite is mined today, much like it was 50 or 100 years ago. The primary difference is that modern miners use pneumatic chipping hammers and mechanical hoists.

Gilsonite, named after Samuel H. Gilson, was discovered in the 1860s. Gilson was not one of the original discovery of Gilsonite, but his enthusiastic development and promotional efforts linked the material to him, and people in the region began refereeing to this material as Gilsonite rather than using its scientific name, “Uintaite”. The name Gilsonite further solidified in common usage when an early mining company adopted and trademarked the name. Much Gilsonite is used directly in its crude form, as insulation for pipelines, particularly hot pipes, as waterproofing and undercoating for wood and metal, and as paving, roofing and other uses identical with crude asphalt. Gilsonite is also blended with refinery produced asphalt and petroleum products to obtain certain desired characteristics. It is used in saturating felts and building construction papers. As underlined previously, the world energy demand is expected to increase due to the expanding urbanization, better living standards, and increasing population. At a time when society is becoming increasingly aware of the declining reserves of fossil fuels besides the environmental concerns, it has become apparent that Gilsonite is destined to make a substantial contribution to the future energy demands of the domestic and industrial economies.

Gilsonite can be dissolved in organic solvents such as carbon disulfide, toluene, and tetrachloroethylene while being insoluble in water and alcohol solvents. Pure Gilsonite contains 70-80% carbon, 15% hydrogen, 5% nitrogen, oxygen, sulfur, metal elements as well as 15-30% volatile organic compounds. The high content of carbon and nitrogen causes specific properties of Gilsonite. The average molecular weight of Gilsonite is 3000 which is higher than other asphalt products and synthetic resins. In terms of composition, it is a quasi-polymer compound.

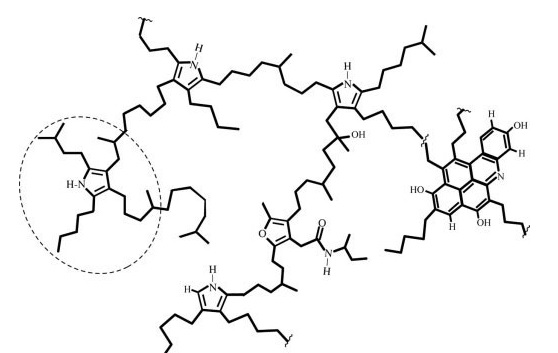

The molecular structure of this compound is as follows:

In the structure of Natural Bitumen, aromatic compounds such as pyrrole, pyridine, furan and phenolic foam with chain aliphatic groups and amide groups are found.

To detect the molecular structure of Natural bitumen, techniques such as FY-IRr NMR, TGA, VPO, HPLC, GC-MASS, CHNOS are used.

Also known as Natural Bitumen (Natural Asphalt) is a Heavy Hydrocarbon formed directly from crude oil reserves, it is produced when the volatile elements of crude oil are evaporated under immense pressure during many years and with specific physical and geographical conditions, therefore Gilsonite is in Solid shape with dark color and high carbon content and based on each mine geology Gilsonite could have different specifications.

Mineral bitumen is our trademarked brand name for uintaite, a naturally occurring hydrocarbon resin with properties that enhance the performance of critical applications across multiple industries, including oil and gas, ink, paint, construction, asphalt, and foundry.

Gilsonite (Natural Asphalt or Natural Bitumen), also recognized as Uintahite or Asphaltum, is a Bitumen-impregnated rock (Asphaltite) that primarily originates from Utah and Colorado in the United States of America and Kermanshah province in Iran. It is a naturally produced solid hydrocarbon bitumen. Although discovered in various other regions around the world, its large-scale production is predominantly observed only in Kermanshah of Iran.

Gilsonite or Uintahite is a naturally produced hydrocarbon resin with properties that improve the performance of critical applications through multiple industries comprising but not limited to oil and gas, ink, paint, construction, asphalt, and foundry.

This distinctive mineral is utilized in more than 160 products, from dark-colored printing inks and paints to oil well-drilling muds and cement, asphalt modifiers, foundry sand additives, and an extensive range of chemical products. This natural asphalt is comparable to hard petroleum asphalt. Thanks to its exceptional compatibility, Gilsonite is often used to harden softer petroleum products. Gilsonite in form is a shiny, black material alike the mineral obsidian. As an additive to asphalt cement or hot mix asphalt, Natural bitumen helps to produce dramatically stabilized paving mixes.

Natural bitumen was formed by a unique geologic event millions of years ago that caused a proto-petroleum deposit forming at that time to fill large surface cracks, later solidifying into the pure resinous rock mined today. Gilsonite is hand-mined in underground shafts using pneumatic jackhammers. We separate Gilsonite by temperature grade, dry and screen it, size it to customer specifications, and submit it to extensive quality control procedures before shipping to over 80 countries worldwide.

Gilsonite Occurrence

Gilsonite occurs in disseminated blebs and in dikes (veins), sills, and fracture fillings, often in association with oil shale or bituminous deposits (tar sands). Gilsonite has a dull, black, coal-like appearance on weathered surfaces and a shiny, black, obsidian-like appearance on a fresh, conchoidal to hackly fracture surface. A small amount of Gilsonite in deep parts of some veins is in a semisolid state or in the form of a liquid ooze. Gilsonite solidifies with increased oxidation of its organic compounds and loss of hydrogen. Industry at one time defined three major subdivisions of Gilsonite based on appearance and fusing temperature: selects seconds, and jet. Selects material is very shiny, fuses from 149°C to 168°C, and tends to occur in centers of veins. Seconds are somewhat duller than selects, fuse from 152°C to 183°C, and tend to occur along vein margins, sometimes with a columnar jointed, “pencillated” texture. Pencillated texture forms at the right angle to vein walls and penetrates about 15 cm into the ore. Gilsonite also has flaky or scaly texture in some localities. A third, unusual variety called jet Gilsonite has a brilliantly shiny surface, is bluish black, and fuses from 199°C to 230°C (Abraham 1960). It was found only in the Cowboy vein. Gilsonite is now classified by fusing temperature into five ranges, which are used in different applications and sell for different prices. Gilsonite from different veins or different parts of veins is sometimes mixed to achieve a product with a specific fusing temperature range.

Global Deposits

Largest bitumen deposits were found in America, Canada, Iran, Iraq, Russia, Venezuela, China, Australia, Mexico and the Philippines, in order of size. The largest deposits are located in Utah and Colorado in the USA. According to the Geological Survey of America, the proven reservoir of theses deposits is estimated about 45 million tons. In general, bitumen reservoirs are found in oil-rich countries- except for Saudi Arabia. World bitumen reservoirs are estimated about 100 million tons. In total, about 65% of world deposits are located in North America, i.e. The USA and Canada, and Iran as the world’s third largest reserve of bitumen accommodated about 15% of deposits, i.e. 15 million tons.

Iran Deposits

Iran’s natural bitumen is of Pyrobitumen type which is primarily solid, and after powdering, classification and initial processing, it can be used in industry. Iran as the world’s third largest reserve of bitumen accommodates about 15% of deposits, i.e. 15 million tons. In Iran, Gilsonite mines are generally located in the West, particularly in Kermanshah, Gilan-e Gharb, Sumar, Ilam, and East of Lorestan. Local names of Qala Qiran (Qala Qilan) Mountain in Ilam suburbs, Tang Qil in Chardavol County, Qylan and Siah-Kal Mountain in Ivan, and Kani Qil in Dehloran imply the presence of known sources of bitumen from the distant past in Ilam Province.

In Iran, Natural bitumen mines were first discovered and mined in 1993. In early stages, they were exported as coal. However, tests revealed that this matter is a bituminous compound with hydrocarbon content, named Gilsonite. Despite the high value of Natural Asphalt, not many works have been done on powdering, packaging, and turning it into other products in Iran. Iran is a Gilsonite producing country providing the high-quality product at lowest price.

Toxicity

Mineral Bitumen is a non-hazardous and non-toxic material and no case of toxicity has been reported so far.

Gilsonite is unsurprisingly superior

Natural Asphalt is safe and non-toxic. It is a very pure resinous rock made of a combination of various hydrocarbons. This distinctive natural combination, rich in nitrogen and beta- carotenes is a highly efficient, versatile, and cost-effective additive for many industrial applications. Gilsonite proposes momentous health benefits over synthetic products.

Gilsonite proposes momentous health benefits over synthetic products.

Natural Asphalt is:

- Non-toxic (unlike coal or fly ash)

- Non-carcinogenic

- Non-mutagenic

- No extreme safety measures are needed to handle Gilsonite

- Passes Gulf of Mexico EPA discharge requirements for deep-water operations.