GILSONITE-DEEP WATER DRILLING

GILSONITE-DEEP WATER DRILLING

GILSONITE IMPROVES PERFORMANCE, EXTENDS THERMAL LIFE AND REDUCED COST IN DEEPWATER DRILLING.

Natural Bitumen has been proven safe and effective in more than 60 years of oilfield performance. Gilsonite is a safe, naturally occurring hydrocarbon resin with unique chemical properties. Added to drilling fluids, it increases performance and reduces cost in deepwater drilling while minimizing risk.

The deeper you look, the more benefits you’ll see

With natural bonding and plugging properties and a high softening point, Gilsonite delivers multiple advantages:

- Extends thermal life 10% or more

- Prevents lost circulation

- Minimizes differential sticking

- Stabilizes shales

- Performs in oil- and water-based drilling muds

- Performs in HP/HT environments

- Reduces cost vs. polymers

- Delivers higher performance with no HSE risk

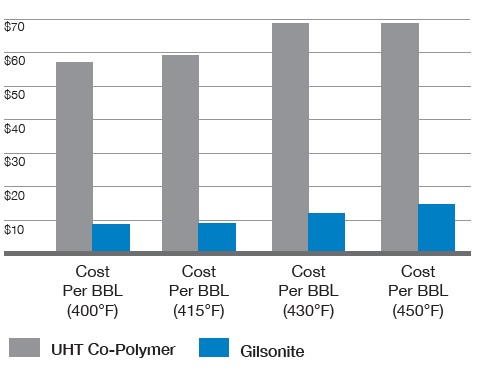

Gilsonite reduces costs more than 80%

At a fraction of the cost of premium polymers, Gilsonite delivers greater cost advantages at higher temperatures:

Gilsonite improves performance at a fraction of the price of synthetics alone.

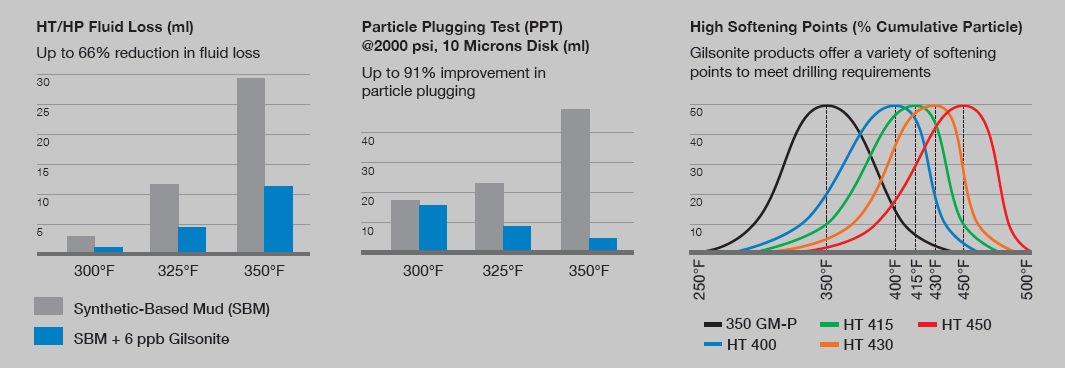

Gilsonite extends thermal life

Gilsonite Corporation’s mines have yielded variations of uintaite with a range of softening points. Carefully selected varieties of pure Gilsonite have been combined to perform to customers’ specifications, at temperatures as high as 500°. Adding Gilsonite extends the thermal life of synthetic-based mud and water-based mud formulations by 10% or more.

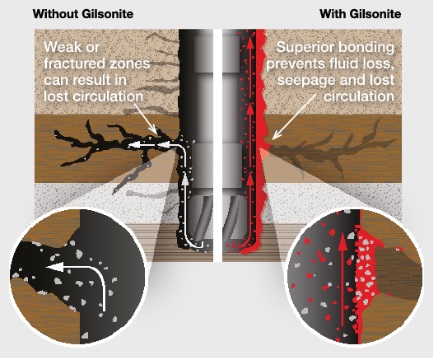

Unique bonding and plugging properties prevent formation damage

Gilsonite forms a physical and chemical bond with permeable formations, creating an effective seal to prevent the passage of drilling fluid. By uniquely functioning as both a malleable and solid plugging agent, Gilsonite controls fluid loss and seepage, prevents lost circulation and protects reactive and low reactive shale surfaces, even at elevated bottom hole temperatures.

A case history: Gilsonite eliminates deep water differential sticking

An international oil company drilling below 16,000 ft. in the Gulf of Mexico encountered a major pressure regression, and the pipe became differentially stuck. Unable to free the stuck pipe, the oil company and the drilling fluids provider decided to sidetrack the well, re-drilling the section with a zero fluid loss WBM. Onsite testing indicated that sized particles and calcium carbonate in combination with high concentrations of Gilsonite resulted in < 0.5 cc HPHT fluid loss, and fluid loss was nil as measured with a permeability plugging apparatus. Using the reformulated WBM, drilling proceeded through the major pressure regression without any sticking tendencies in the problematic wellbore. Gilsonite is proven under pressure.

Gilsonite is naturally better

Gilsonite is a naturally occurring hydrocarbon resin (uintaite) found. Gilsonite has significant health advantages over synthetic products.

> Gilsonite is:

- Non-toxic (unlike coal or fly ash)

- Non-carcinogenic

- Non-mutagenic

> No extreme safety measures are needed to handle Gilsonite

Uintaite Application in Deepwater Operations

GILSONITE-DEEP WATER DRILLING – STUDY PROVES GILSONITE IS SAFE AND EFFECTIVE IN DEEPWATER APPLICATIONS

A new study which evaluated the performance and environmental compliance for Uintaite (Gilsonite) in deepwater drilling operations has revealed that it is a safe and effective means of extending emulsion stability and increasing the temperature threshold in invert emulsion system formulations while fully complying with EPA standards for deep water discharge.

Gilsonite is known to be effective as an additive in a wide range of drilling fluid applications. It controls fluid loss and prevents lost circulation – protecting the formation from damage. Gilsonite is used extensively in onshore and offshore shelf applications around the world. However, its use has been limited in most deepwater areas due to the industry’s widespread belief that Gilsonite (and other asphaltic additives commonly referred to as “black powders”) are detrimental if discharged into a marine environment. The current perception is that Gilsonite use will lead to noncompliance with the Environmental Protection Agency’s (EPA) standards.