Gilsonite as a Borehole Stabilizer

Gilsonite as a Borehole Stabilizer

Summary.

Gilsonite resin is a naturally occurring, mined carbonaceous material classified as an asphaltite. For many years, Gilsonite has been used in drilling fluids as an additive to assist in borehole stabilizer. It has been well documented that this material works efficiently to minimize hole collapse in unstable shale sections. However, because Gilsonite is an asphaltite with a high-temperature softening Point, duplication of its mending action in laboratory tests conducted at ambient temperatures and low pressures has been difficult. New laboratory techniques have been developed only recently to evaluate Gilsonite under simulated downhole conditions. With innovative procedures and a newly built downhole simulation cell (DSC), we tested Gilsonite under temperatures and pressures similar to drilling conditions in which the product would normally be used. These tests indicate that borehole enlargement was minimized by use of Gilsonite while substantial enlargement was measured when the same drilling-fluid system was used without Gilsonite. Another new test procedure was developed to discriminate between various types of Gilsonite products and to determine the most effective product under different temperature and pressure environments. This procedure made use of a high-temperature, high-pressure (HTHP) fluid-loss cell with Berea cores as a filtering medium. Scanning-electron-microscope (SEM) examination of the test cores from both testing procedures provided insight into the mechanisms of how Gilsonite provides stability under downhole conditions. Field data from wells drilled in widely different geological environments support the conclusions reached from laboratory tests.

Gilsonite Hole shale Stabilizer

Gilsonite Borehole stabilizer is a premium grade pre-coupled natural asphalt, blended with select high-temperature resin. Gilsonite Borehole stabilizer offers a variable softening point, ranging from 400 F to 430 F+. Gilsonite Borehole stabilizer is a naturally occurring solid carbonaceous asphaltite material, sourced from select mines of Iran. Gilsonite Borehole stabilizer offers significant advantages over blown, untreated, chemically altered or sulfonated asphalt materials.

Gilsonite Resin as a Borehole Stabilizer

Introduction

For many years. Gilsonite and other asphaltic-type products have been used in water-based drilling fluids as additives to assist in borehole stabilizer. It has been well documented that these additives can minimize hole collapse in formations that contain water-sensitive, sloughing shales. The causes of borehole instability are numerous. The reasons for tile instability can be mechanical. chemical, or physical in nature. The mechanical problems include borehole erosion by high annular velocities, adverse hydraulic stresses caused by high annular pressures, hole collapse from high swab and surge pressures because of excessive wall cake, and stressed erosion resulting from drill string movement. Chemical alteration problems include hydration, dispersion, and disintegration of shales because of the interaction of clays with mud filtrate. Physical instability problems include the spalling and rock bursts of shales caused by subnormal pressure or overpressure relationships of hydrostatic and formation pressures. Fracture and slippage along bedding planes of hard, brittle shales and the collapse of fractured shales above deviated holes are also physical problems encountered during the drilling of troublesome shales. This problem also occurs in non-deviated holes during drilling of over pressured shales. Borehole instability problems are often referred to as sloughing, heaving, spalling, or overpressured shales, mud balls, mud rings, and many other descriptive names. This problem has many solutions. The use of additives to inhibit entirely or partially the swelling of clay has been well documented. The adjustment of hydraulic conditions is another solution to reduce mechanical alteration. Knowing and controlling the pore pressure of the problem formations is used often. In this paper, the use of Gilsonite and asphaltic-type additives to minimize physical and, to some extent, chemical alterations, will be discussed. Evaluating The effectiveness of Gilsonite and other asphaltic-type products in the laboratory has been difficult to evaluate because most test procedures are performed at ambient temperatures and low pressures. Because Gilsonite and some asphaltic-type products require temperature and pressure to be effective, the results of these tests are skewed toward those additives that control shale problems by chemical reaction. These tests do not compare “apples with apples,” but “apples with oranges.” Equipment has been designed recently to study drilling-fluid interaction with formation rock in the laboratory under simulated downhole conditions. One procedure has been used to evaluate the effects of various water- and oil-based mud systems on shale stability under downhole conditions by use of the DSC. This joint industry project, DEA Project 22, was sponsored by the Drilling Engineering Assn. A similar project now being conducted, DEA Project 38, studies performances of asphaltic-type products and Gilsonite in various muds and on different types of shale. Both projects contain proprietary information and will not be discussed in this paper. This paper discusses the results of our independent series of tests on Gilsonite. Gilsonite is a naturally occurring, solid carbonaceous material that is classified as an asphaltite. It is a relatively pure hydrocarbon without significant amounts of mineral impurities. Gilsonite has a softening point of approximately 370F [188C], although a lower softening point, 330F [166C], is available. Other asphaltic-type additives, including air-blown asphalts and sulfonated asphalts, have softening points higher than 240F [116C]. Some of these additives have been treated with a surfactant to provide better water dispersibility or sulfonated to provide various degrees of solubility. According to the suppliers of Gilsonite and other asphaltic-type products, these additives are used to help control sloughing shale problems by minimizing shale slippage along micro-fractures or bedding planes by physically sealing and plugging. We initiated an apples-with-apples study of Gilsonite and asphaltic-type products. Products were evaluated by use of existing testing procedures under ambient temperatures-e.g., triaxial testing for shale stability, lubricity evaluation, and effects on filtration control. The results of the initial test series indicated that a more in-depth evaluation was needed under conditions in which the additives begin to function properly. Several new test procedures that included the use of an altered HTHP fluid-loss cell and a DSC were designed. The results of these tests indicate that these procedures can be used effectively to evaluate and to discriminate between Gilsonite and asphaltic-type products. In addition, the use of the DSC allows the user to discriminate or to rank the effectiveness of Gilsonite and asphaltic-type additives with additives that attempt to minimize borehole instability through chemical inhibition. These procedures allow the user to compare not only apples with apples but also apples with oranges.

Gilsonite Borehole Stabilizer

Theory

As stated previously, Gilsonite is classified as an asphaltite and is a relatively pure hydrocarbon without the significant amount of mineral impurities. Gilsonite used for oil field purposes is mined from an area around Bonanza, Utah, and Kermanshah-Iran and has a specific gravity of 1.05 with a softening point ranging from 370°F to 400°F, although a lower softening point (330°F) material is available. It has a low acid value, a zero iodine number, and is soluble in aromatic and aliphatic hydrocarbons.

Gilsonite and asphaltic-type materials have been used for many years to stabilize sloughing shales to reduce borehole erosion. It is proposed that the material, added to a mud system prior to encountering a problem shale, would penetrate the shale pore spaces, microfractures, and bedding planes as the bit is penetrating the formation. By a plastic-flow mechanism, Gilsonite would extrude into the pores, fractures, and bedding planes to reduce or minimize filtrate and whole mud invasion, and thus bond the matrix to prevent sloughing. Cagle and Schwertner reported that Gilsonite was superior to the blown asphaltic-type additives because of its higher softening point and fewer impurities. Their paper contained photomicrographs of drilled cuttings and cores which showed Gilsonite extruding into pore spaces and fractures. In addition, it has been proposed that Gilsonite plates out on the borehole wall, creating a thin film. Sulfonated, blown asphalts, however, penetrate deeper into the fractures, due to their high solubility, and do not “plate” as well as the insoluble products.

Gilsonite Borehole Stabilizer

Testing Procedures

It has been difficult to duplicate the effectiveness of Gilsonite as a borehole stabilizer in the laboratory, as seen in the field. Several companies have published data conducted at ambient temperatures and pressures. Many of the tests referenced were or are designed for additives which stabilize shale or clay by partial inhibition or encapsulation. Since Gilsonite and the insoluble blown asphalts require both temperature and pressure for extrusion to occur, these additives do not compare favorably in ambient, low-pressure tests. Therefore, to effectively evaluate Gilsonite and asphaltic materials, tests must be designed using higher temperatures and pressures.

The first test, designed and run by Chevron, used existing laboratory equipment. A NL Baroid High-Temperature/High-Pressure fluid loss cell was modified to use a thin 0.5 inch Berea sandstone core as the filter media. (appendix 1) Gilsonite or asphaltic type materials to be tested were dispersed into the base mud slurry. The mud was then placed into the cell, the temperature, and pressure adjusted to specific parameters, the test run, and the filtrate collected and measured. Upon completion of the test, the core was removed. After cooling, the core was sliced and examined under a high-powered microscope. The depth of invasion was measured. Using the same slurry composition, additional tests were performed in which the temperature and pressure were increased to determine effective temperatures at which Gilsonite or the asphaltic materials would extrude into the void spaces of the core and whether a thin, inter-matrix filter cake would develop, or continue to further invade the core. This test is useful to discriminate between insoluble manufactured products such as Gilsonite with different softening points, blown asphalts, and soluble sulfonated blown asphalts. The test can be used to select additives that seal off shale micro-fractures and form a plating film on the face of the borehole.

Following the series of tests which used the HTHP filter press/Berea core, Chevron initiated a study of Gilsonite using the Downhole Simulation Cell (DSC). The apparatus was designed and built by TerraTek Inc., Salt Lake City, under the direction of the O’BrienGoins-Simpson and Associates, Houston. The DSC is a triaxial testing apparatus which can drill through a shale core as large as 6.5 inches in diameter while circulating fluids at temperatures up to 350°F. A schematic of the cell is shown in Figure 1. The complete description of the apparatus can be found in the Simpson, Dearing, Salisbury paper.

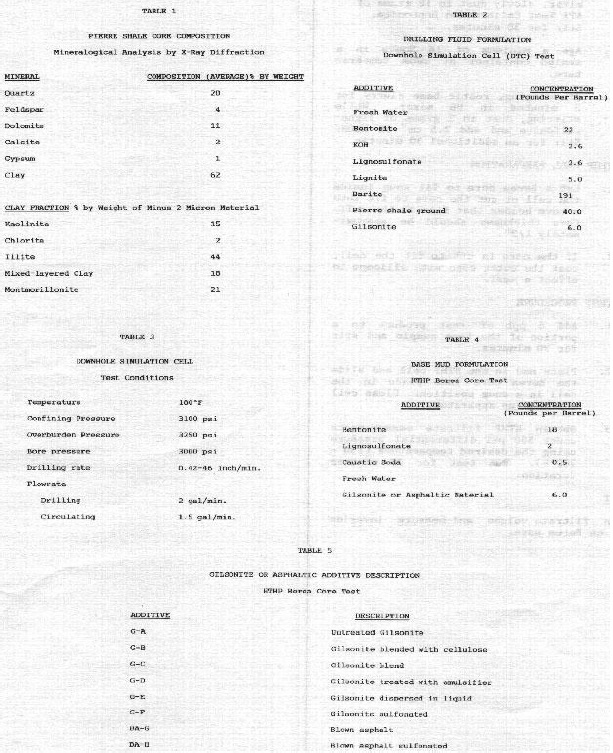

For our purposes, the Pierre shale was used. Table 1 shows a complete mineral analysis of the Pierre Shale core. Table 2 shows the composition of the circulating fluid and the Gilsonite additive, and Table 3, the testing parameters. The first test run confirmed that the DSC could evaluate the effectiveness of Gilsonite under simulated drilling conditions. After this initial success, a series of tests were designed to focus on Gilsonite’s effectiveness under varying temperature and pressure conditions. The investigation also included an evaluation of pretreatment versus treatment after instability occurred and an evaluation of low, normal, and high softening point Gilsonites. The results of this testing program, which will be discussed later in the paper, showed the DCS to be a very effective apparatus for evaluating borehole stability.

Gilsonite Borehole Stabilizer

Test Results

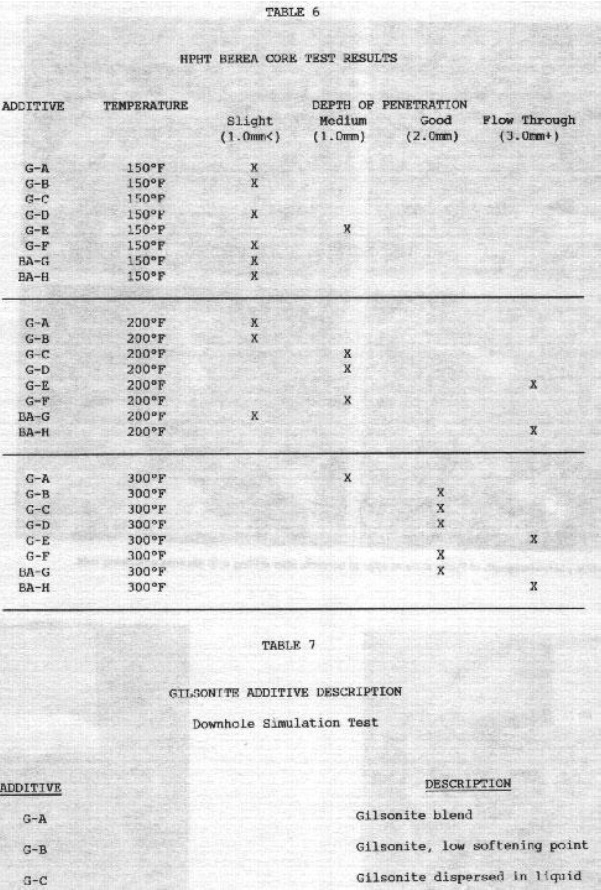

The HTHP fluid loss cell/Berea core test provided data that can be used to discriminate differences between various Gilsonites and asphaltic type additives. Varying temperatures at which the tests were conducted while maintaining the same pressure can distinguish between Gilsonite with varying softening points. Measurement of penetration depth, no penetration, or total invasion or flow through can be used to select a suitable Gilsonite. Table 4 provides the basic drilling mud formulation used in the tests, while Table 5 identifies some of the additives tested along with a generic description of each additive. Many more tests were conducted by our company. The results of some of these tests are shown in Table 6. No penetration or slight penetration by an additive indicates plating at the borehole wall. This indicates that the product is not malleable enough to penetrate into the matrix or there is not enough temperature and pressure to allow the additive to extrude. Deeper penetration shows that the temperature and pressure are enough for extrusion to occur. Complete invasion or flow through the core indicates that additive has been treated for dispersibility and solubility and does not plug or form an inter-matrix filter cake.

An inspection of the core cross-section showed the formation of a thin inter-matrix filter cake with the Gilsonite products. Penetration was limited to less than 2mm. A thin film was formed on the surface of the cores, and definite plugging action was observed.

Inspections of the cross-section of a core using a sulfonated blown asphalt manufactured to be approximately 70% soluble shows no plugging action. Additional tests were performed at 250°F and 350°F temperatures while constant pressure was maintained on the cells. In this test, Gilsonite, although processed differently by manufacturers, but with the same softening point, could be discriminated. Several formed an inter-matrix filter cake while others only plated out at the surface. Gilsonite with a lower softening point showed deeper penetration than the higher softening point Gilsonites. The results of this test indicate that the procedure can be used to discriminate between Gilsonites, blown asphalts, and sulfonated blown asphalts as to the degree of plugging action under varying temperature and pressure conditions.

The results of the DSC tests indicate that the apparatus can be valuable in evaluating the effectiveness of additives such as Gilsonite or asphaltic type materials. The Pierre shale core was exposed to a circulating drilling fluid for 45 hours. After 45 hours of exposure, the borehole size of the core sample increased from 1.25 inches to 2.25 inches, an increase of 80%. Table 7 lists a generic description of various Gilsonite additives used in the tests.

In addition, a core was exposed to the same drilling fluid with an addition of six pounds per barrel of a blended Gilsonite. The borehole did not show any evidence of hole enlargement after an identical 45 hours of exposure and teeth marks from the bit can be seen. On the initial examination of the borehole wall, a thin, soft, tacky film of malleable Gilsonite could be observed. Another core was also exposed to the same fluid composition containing the blended Gilsonite; however, the test temperature was lowered from 180°F to 125°F. Hole enlargement measured an average of 1.56 inches, a 25% increase, and the film was not observed in the core. The lower temperature tests were used to define temperature limitations of this additive.

To confirm that softening point of Gilsonite’s has some effect on its effectiveness. Gilsonite with a low softening point was selected. Figure 6 shows a core exposed to a low softening point 330°F Gilsonite, at 125°F circulating temperature. The average hole size nearly gauges, with no enlargement.

To confirm that softening point of Gilsonite’s has some effect on its effectiveness. Gilsonite with a low softening point was selected. Figure 6 shows a core exposed to a low softening point 330°F Gilsonite, at 125°F circulating temperature. The average hole size nearly gauges, with no enlargement.

Another test was designed to determine the effectiveness of Gilsonite treatment after hole instability signs were observable. The core was exposed to the base drilling fluid for 15 hours to initiate hole enlargement, then a treatment with blended Gilsonite was initiated. Enlargement was measured at 2.0 inches as compared to 2.25 inches in the control sample. A film of Gilsonite was observed; however, the film was gummy and not as tough as the sample at 125°F. This test indicates that pretreatment is more effective; however, treatment after observable signs of borehole instability can still mitigate the problem. We also examined the effectiveness of a Gilsonite suspension in a liquid. The core was exposed to such a fluid at a concentration of 4% Gilsonite in suspension. Enlargement was 0.25 inches over the initial size, an increase of 20%. No borehole plating was observed. This observation was similar to the results of the high-temperature, high-pressure filter cell/Berea core test.

To help verify our proposed mechanism explaining the effectiveness of the Gilsonite for preventing shale instability, the alumina core experiments were set up as described in the procedures section. The resulting photomicrograph for the plug injected with Gilsonite containing drilling fluid at room temperature shows a very thin filtercake with the drilling fluid solids penetrating not more than about 200 um (0.2 mm) into the core. This penetration depth is supported by the corresponding EDX pattern, ie. the silicon peak reflecting the siliceous drilling fluid solids and the silicon contaminant in the Gilsonite disappears below the midpoint of the montage.

The montage of photomicrographs for the core injected with the same Gilsonite drilling fluid at 250°F shows an equally shallow depth of penetration for the drilling fluid solids despite the fact that there was more fluid lost to the plug during this test. Apparently, the Gilsonite used in this test is not very fluid even at 250°F.

Gilsonite Borehole Stabilizer

Test Interpretation

The results of the two series of tests indicate that these novel procedures can be used to determine the effectiveness of Gilsonite and asphaltic type additives. Test procedures conducted at ambient temperatures should not be used. The Berea core test can be used to provide some measurement of the temperature and pressure conditions in which these additives can be used. Selection can depend upon melting point and dispersibility of the drilling fluid. The tests indicate that additives treated for a high degree of solubility do not effectively plug the borehole surface or even form a slight inter-matrix filter cake. With these additives, deep invasion does result.

The DCS tests indicate that evaluating these additives under simulated downhole conditions are effective. The tests show that when Gilsonite used in sufficient concentration in a KOH/lignosulfonate can minimize hole enlargement in a Pierre shale. However, the tests clearly show that there are temperature limitations and a low softening point Gilsonite should be used in wells with low circulating temperatures.

Examining cores using high-powered microscopy provides some insight into the way Gilsonite works. With sufficient temperature and pressure, the additive becomes malleable and intrudes into micro-fractures, pore spaces, and bedding planes of the shales. This bonding action “mends” or holds clay platelets together, thus preventing further shale disintegration. In addition, the “tail” of the Gilsonite particle plates or attaches to the borehole wall, forming a tough film which appears to strengthen the wall against the erosional effects of the drilling fluid. The performance of the Gilsonite additive in a drastically different drilling fluid, such as a salt/polymer system, or with a drastically different shale, such as one containing no smectite, might differ considerably from these results and could best be determined by additional DSC testing.

Gilsonite Borehole Stabilizer

Field Data

The results of these tests are supported by field data in which Gilsonite was used to provide borehole stability. Chevron is using the product in many environments, but only three wells are cited.

In the South Pass area, offshore Louisiana, a blended Gilsonite-lignite was used to reduce torque and drag. Normally wells in this area are deviated approximately 30° from vertical and are drilled with a conventional lignosulfonate mud. On well A, conventional and bead-type lubricants have been used for torque and drag reduction. On well B, 3 lbs/bbl Gilsonite was added at approximately 10,600 feet, measured depth. By comparison, the torque on well B was reduced on an average from 1400 foot-pounds to 900 foot-pounds, a 36% reduction, and drag on an average from 60,000 pounds to 30,000 pounds, a 50% reduction. Caliper log comparisons from these two wells indicate substantial improvement with the use of the blended Gilsonite/lignite.

Another well was drilled in the Eugene Island area of offshore Louisiana. While this area is not known for borehole instability, hole enlargement, however, is a problem. Prior to the introduction of a Gilsonite additive, hole enlargement averaged approximately 50% in a 12.25-inch hole. At the casing point, 4% Gilsonite suspended in a water-based solution, was added to a conventional lignosulfonate mud system. In addition to borehole stability, the Gilsonite suspension provided both rheological and fluid loss control. Hole enlargement in the 8.5-inch hole was reduced to an average of 15%.

On a third well recently drilled by Chevron in the Evanston, Wyoming area, hole instability was encountered. The area is in the thrust fault zone known as the hinge line. In this part of the field, hole instability is frequently encountered. On this well, excessive torque and drag, bridges after trips, and reaming problems continued to increase. An inhibitive, KOH-gypsum mud system was being used and chemical alteration was not indicated by the cuttings. An onsite analysis by Chevron employees suggested that tectonic stresses probably caused borehole instability. A hole cleaning program was initiated first by viscosifying the mud by increasing the YP from 7 to 15 lbs/100 ft². Secondly, 5 pounds per barrel of a blended Gilsonite was added to the system. Within two days, hole stabilization was achieved and drilling continued without further instability problems.

These well histories confirm the results of the testing program conducted by our company. First, Gilsonite additives, used in sufficient concentration, provide borehole stability and reduce hole enlargement significantly. Second, Gilsonite should be used as a pretreatment; however, it can be used successfully even after borehole instability has occurred.

Gilsonite Borehole Stabilizer

Conclusions

Based on the results of the testing program our company has conducted and comparing these results with some well histories, the following conclusions are offered.

1. To monitor the effectiveness of a Gilsonite or asphaltic-type product, laboratory tests should be conducted under simulated downhole conditions. One of the most effective laboratory apparatus is the Downhole Simulation Cell.

2. There are differences in Gilsonite additives as to their effectiveness at varying temperatures and to some degree pressure. A simplified high-temperature high press filtration cell using a Berea core as a filtering medium can be used to discriminate Gilsonite products and asphaltic type products concerning plugging ability.

3. Gilsonite is an effective additive as a Borehole Stabilizer. The additive plugs off microfractures, bedding planes, and pore spaces, and deposits a thin film on the borehole wall which mitigates hole erosion. It is recommended that Gilsonite be added to a system prior to drilling shale sections where borehole instability is expected. However, laboratory tests do indicate that treatment after destabilization has been initiated to be effective with minimum concentration values of 3-4 pounds per barrel.

Our company concludes that the downhole simulation cell can be used to evaluate additives which stabilize troublesome shales either through a mechanical action such as Gilsonite or a chemical action such as inhibition. Under these test conditions “apples can be compared with oranges”.

Gilsonite Borehole Stabilizer

Acknowledgment

The authors wish to express appreciation to Marion Reed, Chevron Oil Field Research Company, Bob Haffner, Clyde Parrish and Clark Christensen, American Gilsonite Company for the assistance in writing this paper. We acknowledge the support of J. D. Combes and T. B. Sumner, Chevron Services for the initiation and completion of the project, and to Chevron Services for permission to publish this paper.

References

1. W. S. Cagle and L. F. Schwertner, “Gilsonite Borehole Stabilizer Sloughing Shales”, Oil and Gas Journal, March 27, 1972.

2. J. L. Lummas, “Op Drilling and Holemaker Mud Cut Williston Basin Costs”, Oil and Gas Journal, April 17, 1972.

3. D. La Hue and G. Schooler, “Polymer Retards Water Loss In Shale Formation During Rig’s Lengthy Shutdown”, Drilling, August 1983.

4. D. B. Anderson and C. D. Edwards, “Fluid Development For Drilling Sloughing and Heaving Shales”, Petroleum Engineer International, September 1977.

5. J. P. Simpson, H. L. Dearing, and D. P. Salisbury, “Downhole Simulation Cell Shows Unexpected Effects of Shale Hydration on Borehole Wall”, IADC/SPE Conference, SPE17202, February 28, 1988.

6. H. Abraham; “Asphalts and Allied Substances”, Volume I Raw Materials and Manufactured Products, D. Van Nostian Co., Inc. NY City, 1945.

7. Field, L. J. “How Solids Non-Dispersed Mud Usage in Western Canada “, presented at API meeting, Calgary, Alta, May 1968.

8. Drilling Specialties Company, “Soltex Shale Inhibitor”, Technical Sales Memorandum, 1986.

9. J. A. Wingrave, E. Kubers, Jr., C. F. Dority, D. L. Whitfill, and D. P. Cords, “A New Chemical Package Produces An Improved Shale-Inhibitive Water-based Drilling Fluid System”, SPE 16687, Presentation at SPE Fall Technical Conference, September 1987.

10. F. F. Sullivan, “Drilling Fluid Treatment” -application No.109, 136, Canadian Patent, January 20, 1971.