GILSONITE BENEFITS-ASPHALT PAVEMENT

GILSONITE BENEFITS-ASPHALT PAVEMENT

SCIENTIFIC STUDY PROVES GILSONITE BENEFITS IN ASPHALT PAVEMENT

A 2015 study by the Western Regional Superpave Center at the Department of Civil and Environmental Engineering of the University of Nevada, Reno, proved that Gilsonite-modified binders significantly extend the useful life of asphalt pavement. This is good news for agencies looking to reduce the long-term costs of asphalt pavement maintenance.

Findings from comprehensive testing demonstrated that Gilsonite-modified binders showed significant improvement in:

- Tensile strength – The addition of Gilsonite significantly increased both the unconditioned and moisture-conditioned tensile strength.

- Compressive strength – Gilsonite-modified binders showed significant improvement in compressive strength.

- Rutting strength – Gilsonite-modified binders significantly increased projected pavement life. In all but one case, adding Gilsonite yielded a ten-fold increase.

- Fatigue resistance – The projected pavement life is 1.5 to 5 times longer with the Gilsonite-modified binders.

Gilsonite Benefits-Asphalt Pavement – Gilsonite reduces material and saves money

Gilsonite increases the viscosity of asphalt so roadways resist deformation and fatigue, even under temperature extremes – unlike other modifications or high modulus asphalt based on RAP.

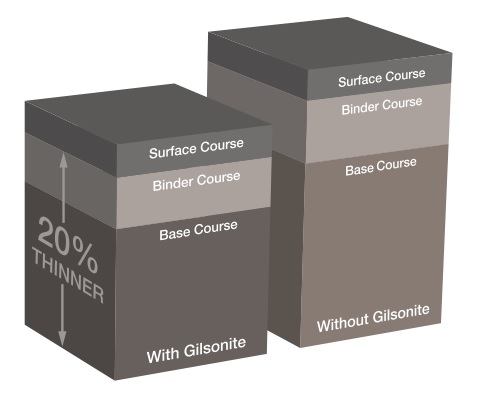

Industry reports of Gilsonite-modified asphalt lasting more than twice as long as unmodified mixtures are common. In addition, the high modulus provided by Gilsonite allows the base and binder courses to be up to 20% thinner while still providing the same level of performance, enabling the use of less material. Gilsonite can also act as a lower-cost, performance-enhancing extender in a mixture including SBS polymers.

By significantly extending the useful life of asphalt pavement and allowing a reduction in the amount of paving material required, Gilsonite has proven to offer substantial cost effectiveness.

Gilsonite Benefits-Asphalt Pavement – Gilsonite is superior for recycling asphalt

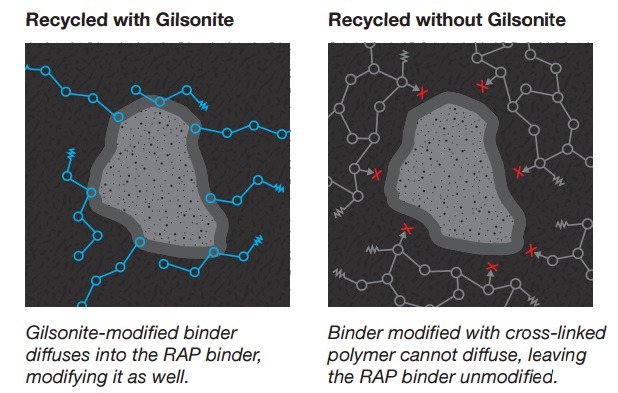

Only Gilsonite-modified binder bonds with and stabilizes recycled binder, making recycled asphalt as strong and durable as new. By contrast, polymer-modified binders form large molecules that cross-link into a matrix that recycled binder cannot bond with, leaving pavement vulnerable to breakdown.

Gilsonite Benefits-Asphalt Pavement – No other additive can match all the benefits of Gilsonite:

- High strength and fatigue resistance

- Reduced temperature susceptibility

- Superior deformation resistance

- Increased resistance to water stripping

- Reduced pavement thickness

- Safe and environmentally responsible

Gilsonite Benefits-Asphalt Pavement – Gilsonite is proven to perform

Gilsonite’s unique properties make a road that is less susceptible to high-temperature and deformation performance issues. Gilsonite can be added directly at the hot mix plant without additional equipment.

Gilsonite Benefits-Asphalt Pavement – Gilsonite makes roads stronger

to last longer Compared to a typical road that might last 10 years, Gilsonite produces a stronger, better-bonded asphalt that can last 25 years.

Gilsonite Benefits-Asphalt Pavement – Use Gilsonite as a cost-effective component of modified polymer

Modified polymer additives can increase binder performance under certain extreme conditions. However, SBS polymers cost more than twice as much as Gilsonite. A more cost-effective solution is to combine Gilsonite and SBS polymers to achieve the desired grade.

Gilsonite Benefits-Asphalt Pavement – Asphalt with Gilsonite resists rutting

Gilsonite increases the viscosity of asphalt so roadways resist deformation and fatigue, even under temperature extremes – unlike other modifications or high modulus asphalts based on RAP.

Gilsonite Benefits-Asphalt Pavement – Gilsonite outperforms other bitumen modifiers

- Unique source with high purity deposits

- Extracted with little contamination

- Ideal softening point for bitumen modification

- Natural antioxidation properties resist age hardening and degradation

Gilsonite Benefits-Asphalt Pavement – Building stronger roads for more than 100 years

Gilsonite is the trademarked name for uintaite, a natural asphalt discovered in the Uinta Basin of northeastern Utah. Since the 1860s, RAHA Gilsonite Company has been producing Gilsonite to strengthen asphalt roads. Gilsonite is readily available in meltable bags.

Gilsonite is versatile, cost-effective and adds a new dimension of strength to asphalt.

Gilsonite is a naturally occurring hydrocarbon resin that adds tremendous strength, durability, and longevity to asphalt roads. It is a cost-effective additive with unmatched performance.

Evaluation of Gilsonite-modified asphalt mixtures

Cost-effective additive improves strength, reduces rutting and cracking

Gilsonite has been used as an additive to enhance the performance of asphalt pavements for more than 100 years. While field experience had demonstrated the advantages of using Gilsonite, the unique properties of Gilsonite-modified asphalt had not been well-documented due to the lack of a comprehensive evaluation.

However, a 2015 study by the Western Regional Superpave Center at the Department of Civil and Environmental Engineering of the University of Nevada, Reno, thoroughly analyzed various asphalt pavements using the latest advancements in materials testing, pavement modeling, and life-cycle analysis.

Key points of the study

The evaluation was conducted under rigorous standards:

> An independent supplier provided control samples and Gilsonite-modified versions of two performance grades (PG) of Asphalt: PG64-28, indicating performance engineered for a pavement temperature range of 64°C to –28°C; and PG76-16, designed for a pavement temperature range of 76°C to –16°C.

> All asphalt binders met the applicable state highway agencies’ specifications based on the Superpave PG System for Asphalt Binders.

> The optimum binder content (OBC) of each asphalt mixture was identified by following the Superpave Volumetric Mix Design Method.

> Laboratory equipment included the industry recognized Asphalt Mixture Performance Tester (AMPT).

> The engineering properties of the asphalt mixtures were measured at their OBCs in terms of the dynamic modulus E* master curve.

> The following performance characteristics of the asphalt mixtures were evaluated:

- Resistance to rutting in terms of the Flow Number

- Resistance to thermal cracking in terms of fracture temperature and fracture stress

- Resistance to fatigue cracking in flexural bending

Quantifying performance

Gilsonite has long been used to increase the performance of asphalt binders. Now, the respected study has documented its advantages.

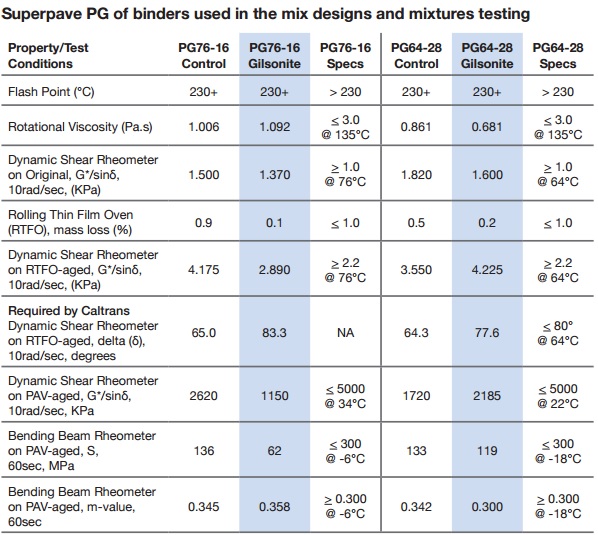

Superpave PG characteristics used in testing

The Superpave Performance Grading (PG) system uses the rheological properties of the asphalt binder to identify its performance under the prevailing environmental conditions at the location of the project. The characteristics of the binders used in the testing are summarized in the table below.

A close examination of the data shows that the addition of Gilsonite to the PG 76-16 mixture resulted in an asphalt binder that is less susceptible to short-term and long-term aging.

The industry standard

The most commonly used asphalt binder specification in the U.S. is the Superpave Performance Grading (PG) system.

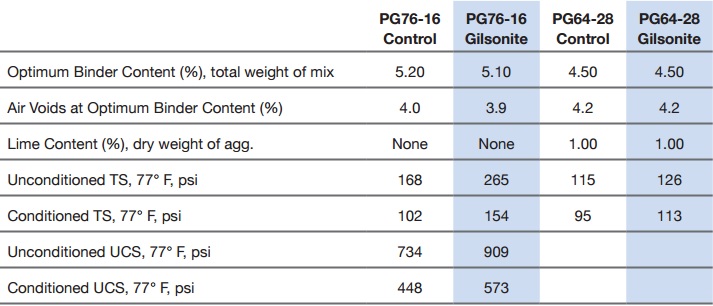

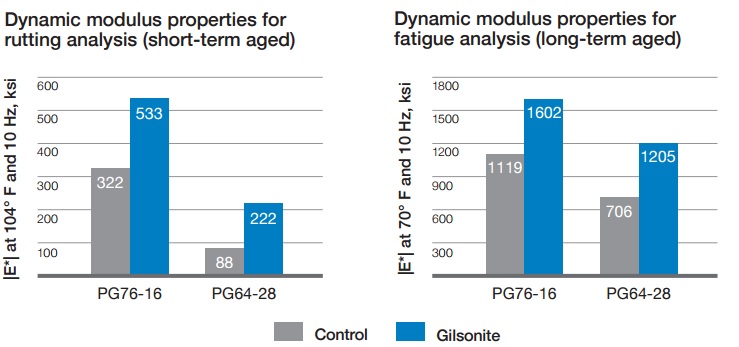

The same amount of binder, significant increases in strength

The Superpave system determines optimum binder content (OBC) based on an air voids level of 4% while meeting the remaining specified volumetric properties. Tests showed that the OBC was comparable for control samples and Gilsonite modified samples. The PG64-28 mixtures required the addition of hydrated lime in order to meet moisture sensitivity specifications. Gilsonite modified binders showed significant improvement in both tensile strength (TS) and unconfined compressive strength (UCS).

Summary of optimum binder contents and lime contents, unconditioned and moisture-conditioned TS and UCS properties of the various mixtures

Dynamic modulus (E*) represents strength and stability

The American Association of State Highway and Transportation Officials (AASHTO) Mechanistic-Empirical Design uses the dynamic modulus (E*) master curve as the engineering property of the asphalt concrete layer to evaluate the structural response of asphalt pavement under various combinations of traffic loads, speed, and environmental conditions.

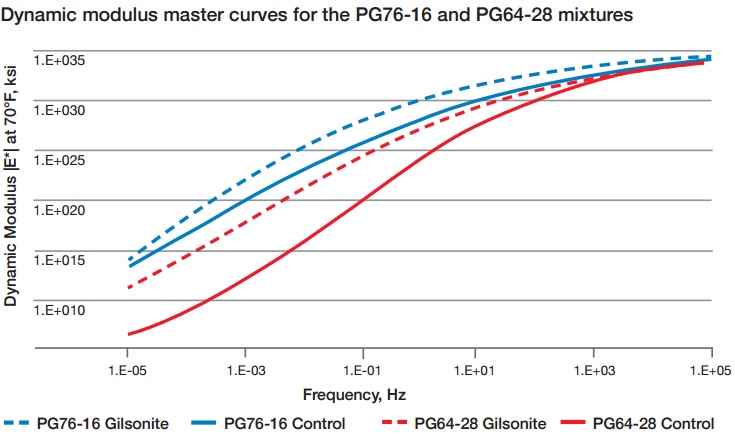

A higher E* property indicates a stronger, more stable mix and leads to lower stresses generated in the asphalt pavement under given loading and environmental conditions. The master curves data in the figure below indicate that the Gilsonite mixtures exhibit significantly higher E* properties compared to the control mixtures over the entire range of loading frequency.

Capturing a range of variables

The dynamic modulus curve represents various combinations of loading frequency and temperature.

The data in the charts below compare the E* property of the mixtures at 10Hz loading frequency representing a truck traveling at 60 mph (108 kph). The 104° F (40° C) and 70° F (21° C) temperatures were selected since they represent the critical temperature of rutting and fatigue, respectively.

Gilsonite helps reduce rutting

Gilsonite increases the viscosity of asphalt so roadways resist deformation and fatigue, even under temperature extremes.

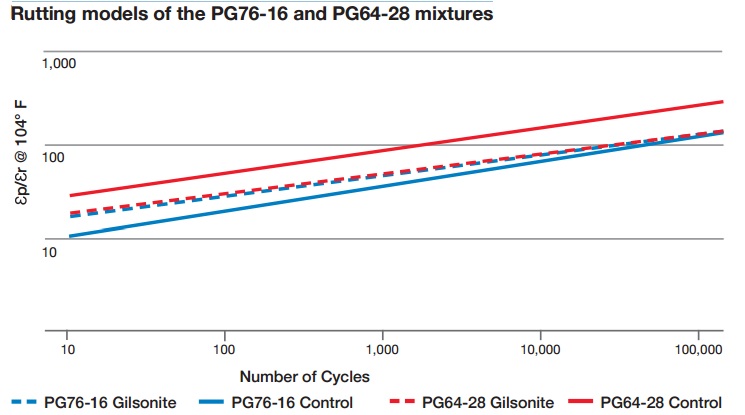

Resistance to rutting

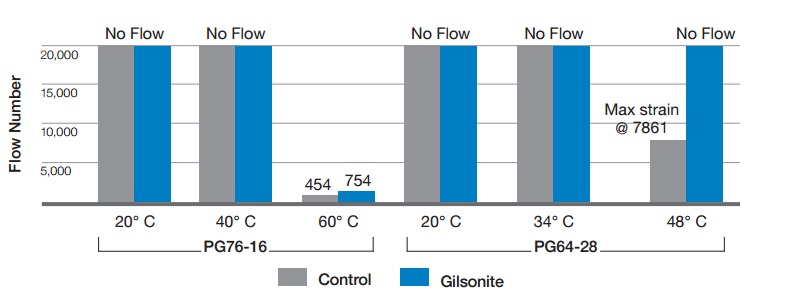

The flow number property was evaluated to assess the rutting resistance of mixtures and to determine the rutting models coefficients.

The figure below compares the rutting models of mixtures. The PG64- 28 Gilsonite-modified mixture exhibited a lower rutting model at 104°F (40°C) than the control mixture, indicating that the Gilsonite mix would offer higher resistance to rutting. The PG76-16 Gilsonite-modified mixture exhibited a slightly higher rutting model at 104°F (40°C) than the control mixture.

As shown below, adding Gilsonite to the PG76-16 mixture increased the flow number at 60°C (140°F) by 66% (754 vs. 454). The addition of Gilsonite to the PG64-28 mixture resisted the tertiary flow at 48°C (118°F). This indicates that Gilsonite-modified mixtures will offer significantly more resistance to rutting at the elevated pavement temperature.

Flow numbers of the PG76-16 and PG64-28 mixtures

Relevant sample preparation

Since rutting is an early pavement life failure, the mixtures for the flow number test were only short-term aged.

Resistance to thermal cracking

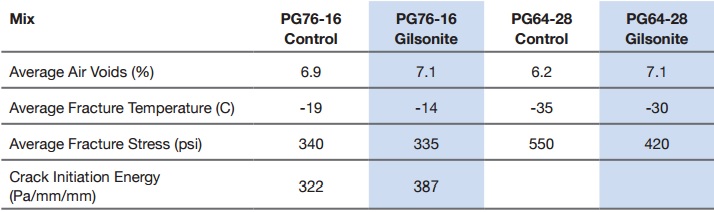

To determine an asphalt mixture’s ability to withstand low temperatures without cracking, tests measured both the temperature at which fracturing occurred as well as the stress required to initiate fractures.

In the PG64-28 samples, both the control and the Gilsonite modified binders exceeded cold temperature specifications and thus were not expected to crack. The Gilsonite-modified PG76-16 sample showed cracking at 2°C warmer than specifications. However, the calculated crack initiation energy was 20% higher than the control, so it would not be expected to crack under normal conditions.

Thermal cracking properties of the evaluated mixtures

Resistance to fatigue cracking

The resistance of the various mixtures to fatigue cracking was evaluated using the flexural beam test wherein a beam specimen was subjected to a constant bending moment over the center portion of the specimen. Initial flexural stiffness was measured at the 50th load cycle. Fatigue failure was defined as the number of cycles corresponding to a 50% reduction in the initial stiffness.

Figures below compare the fatigue models of mixtures. The cycles-to-failure tests showed similar results for the PG76-16 control and Gilsonite modified samples. In the PG64-28 mixtures, the control sample exhibited slightly higher fatigue relationships than the Gilsonite mixture. It should be noted, however, that the calculated values do not account for the effect of the much higher E* in the Gilsonite-modified binder.

Fatigue cracking models for the PG76-16 and PG64-28 mixtures at 70°F

Testing at the right time

Thermal cracking and fatigue cracking are later pavement life failures, generally occurring after five years. Test mixtures were aged accordingly.

Mechanistic analysis assesses effect of actual conditions

In addition to sophisticated laboratory tests, the university’s evaluation included mechanistic analysis. A lab test designed to compare the fatigue cracking models of two asphalt mixtures only assesses the relative behavior of the mixtures without any indication on their relative impacts on pavement life.

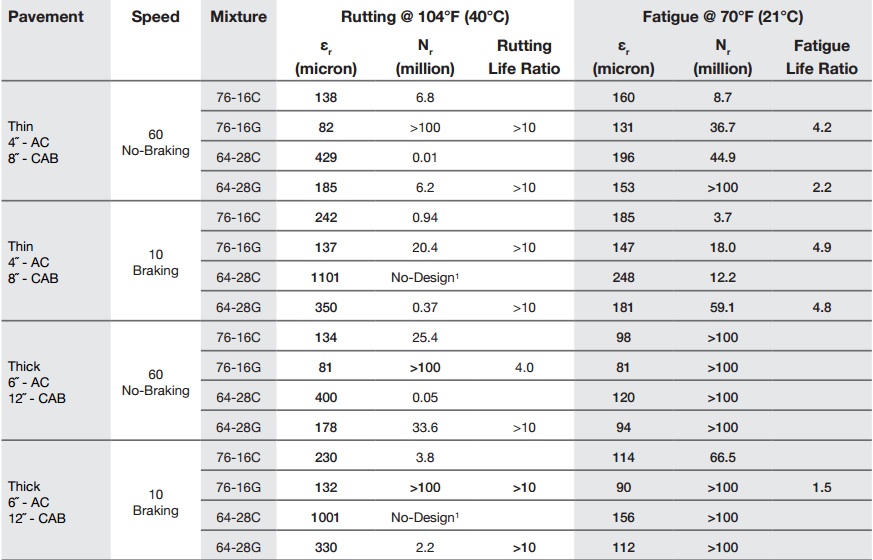

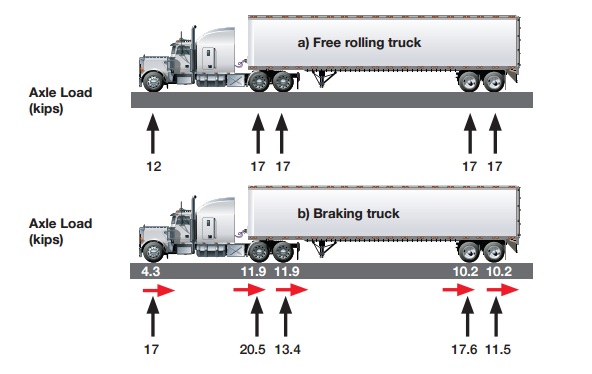

The main advantage of the mechanistic analysis is its ability to combine the engineering property of the asphalt mixture (E*) with its rutting and fatigue cracking characteristics to determine the true impact of traffic loads on pavement life. The analysis evaluated thin pavements – <4” asphalt cement (AC) layer and 8” crushed aggregate base (CAB) layer – and thick pavements – 6” AC layer and 12” CAB layer. Dynamic conditions included the heavy load imposed by a legally loaded 18-wheeler traveling at 60 mph (96 kph) without any braking, and traveling at 10 mph (16 kph) with braking.

The mechanistic analysis of rutting resistance demonstrated that the Gilsonite-modified mixtures had ten times the projected pavement life in every instance except one. For fatigue resistance, the Gilsonite-modified mixtures had a projected pavement life of 1.5 to almost 5 times that of the control mixture.

Summary of the comparative mechanistic analyses of the various mixtures

In theory and in practice

Mechanistic analysis completes the picture begin with lab testing.

Vertical and horizontal forces affecting pavement life

When an 18-wheeler is in the free rolling condition, the vertical loads are distributed evenly among the various axles. Under braking, there is a significant re- distribution of the vertical loads among the axles and the development of significant horizontal loads at the tire/pavement interface. These horizontal loads significantly increase the shear and vertical stresses within the AC layer and represent the main cause of accelerated failures in rutting and shoving at intersections and on off-ramps.

Distributions of axle loads for 18-wheeler at free rolling and braking conditions

Mechanistic analysis findings:

- The PG64-28 control mixture cannot be adequately designed to withstand the braking action of the 18- wheeler for both the thin and thick pavement structures.

- The PG76-16 and PG64-28 Gilsonite-modified mixtures significantly improved the rutting life of the thin and thick pavements under the no-braking and braking conditions.

- The PG76-16 Gilsonite mixture significantly improved the fatigue life of the thin pavement under the no-braking and braking conditions.

Bearing the load

The mechanistic analysis shows which mixtures significantly improved road life.

Specific conclusions and recommendations

In summary, the evaluation program concluded that the addition of Gilsonite to the PG76-16 neat and PG64-28 polymer-modified asphalt binders resulted in unique, measurable characteristics that offer excellent alternatives in the following situations:

- The PG76-16 mixture provides extremely high resistance to rutting and shoving with excellent long-term aging characteristics for use in the wearing course of asphalt pavements.

- Both the PG76-16 and PG64-28 mixtures provide extremely high resistance to fatigue cracking beneficial for use as the binder/base course of Perpetual asphalt pavements.

- The PG64-28 mixture can successfully withstand the braking actions at traffic lights on urban streets and off-ramps.

Cost effectiveness

By imparting properties that increase resistance to rutting, shoving and fatigue cracking, the addition of Gilsonite can significantly extend the useful life of asphalt pavement. Industry reports of Gilsonite modified asphalt lasting more than twice as long as unmodified mixtures are common.

In addition, the high modulus provided by Gilsonite allows the base and binder courses to be up to 20% thinner while still providing the same level of performance, enabling the use of less material.

Gilsonite can also act as a lower-cost, performance enhancing extender in a mixture including SBS polymers.

By significantly extending the useful life of asphalt pavement and allowing a reduction in the amount of paving material required, Gilsonite has proven to offer substantial cost effectiveness.