Fluid Loss Control (FLC)

Drilling Gilsonite – Fluid Loss Control (FLC)

What Is Gilsonite

Gilsonite is mined in underground shafts and resembles shiny, black substance similar in appearance as the mineral Obsidian It is brittle and usually micronized into dark brown powder. It is mainly composed of asphaltenes; thus, Gilsonite Is classified as a Natural Asphalt and also known as uintaite or uintahite. Discovered in the 1860s, it was first marketed as a lacquer, electrical insulator, and waterproofing compound. This unique mineral is used in more than 160 products, primarily in dark-colored printing inks and paints, oil well drilling muds and cement, asphalt modifiers, foundry sand additives, and a wide variety of chemical products.

What are Asphaltenes

Asphaltenes are molecular substances that are found in crude oil, along with resins, aromatic hydrocarbons, and alkanes (i.e., saturated hydrocarbons). The word “asphaltene” was coined by Boussingault in 1837 when he noticed that the distillation residue of some bitumen had asphalt like properties. Asphaltenes in the form of distillation products from oil refineries are used as “tar-mats” on roads. Asphaltenes consist primarily of carbon, hydrogen, nitrogen, oxygen, and sulfur, as well as trace amounts of vanadium and nickel. The C:H ratio is approximately 1:1.2, depending on the asphaltene source. Asphaltenes are defined operationally as the n-heptane (C7H16)-insoluble, toluene (C6H5CH3)- soluble component of a carbonaceous material such as crude oil, bitumen or coal. Asphaltenes have been shown to have a distribution of molecular masses in the range of 400 u to 1500 u with a maximum around 750 u.

Fluid Loss Control (FLC) – Gilsonite use in Drilling sector

Gilsonite is used in drilling fluid loss control (FLC) and oil well cementing. Gilsonite, in a range of softening points and particle sizes, is a standard ingredient in oil-based drilling muds used in shale and other difficult geological formations. The addition of specially-treated Gilsonite to water-based drilling fluids helps minimize hole washout by stabilizing troublesome shale and seals off highly permeable sands while reducing torque and drag. The addition of Gilsonite to oil well cement reduces slurry weight without loss of compressive strength and acts as an effective bridging and plugging agent to seal fractures in weak formations while cementing The maintenance of circulation of the drilling fluid is essential to successful drilling by the rotary method. The drilling fluid loss control or mud is supplied at the surface of the well in large earthen pits or metal tanks and is pumped from these into the borehole through the drill pipe and the drill bit to the bottom of the hole. The mud returns to the surface between the drill pipe and the borehole wall, bringing with it the drill cuttings. The circulation of the mud serves not only to carry the cuttings to the surface but also to cool and lubricate the drill bit, thus making possible the further effective penetration of the bit into deeper geological strata. In conventional drilling operation a drilling mud based on bentonite or other materials such cane fiber, ground walnut hulls, sawdust etc. is commonly used, but The solid organic materials used are difficult to keep suspended in the drilling fluid, being of a higher specific gravity than the fluid, while materials such as expanded perlite, though easily to suspend, become compressed to a specific gravity higher than that of the fluid under the bore hole. Furthermore, the commonly used materials lack adhesive power and are insoluble, and they have been known to become lodged in the wall of the borehole so as to obstruct or seal off a producing oil or gas zone, thus causing a costly or even a complete loss of production. To prevent Lost Circulation is needed a material with following specifications:

- Incompressible material

- Specific gravity lower than the fluid

- Solubility

- Adhesive power

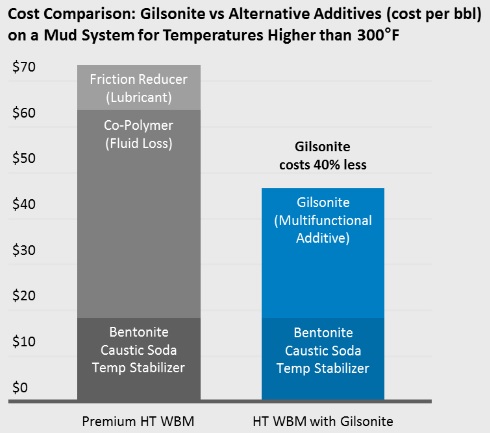

Gilsonite also is known as uintahite or asphaltum is considered the most economical multi-functional additive for all types of mud. Research shows, Gilsonite, thanks to its distinctive chemical properties and physical features, is an ideal agent in improving wellbore stability, plugging micro-fractures, and bonding and sealing any type of formation. Gilsonite owes its cost-effectiveness to that it allows for use of fewer additives for your applications.

All the common varieties of Gilsonite are substantially incompressible and have a specific gravity sufficiently near to that of water that properly sized granules of the Gilsonite can be readily suspended in the aqueous liquid carrier. Thus, Gilsonite is used for this purpose in powder. Particle size (mesh) is variable according to the characteristic of the wellbore. The softening point is very important as Gilsonite must soften at a temperature above the temperature of the well formation. The first patent, dated 1954, indicated the use of a Gilsonite with softening point from 150 to 180°C and mesh from 4 to 100.Actually, with more technological devices, the most commonly used is 200/200 (softening point/mesh) type; by the way, Groupeve can supply Gilsonite in a range of 40/400 mesh and 140/230°C softening point.

Gilsonite- Drilling Fluid Loss Control (FLC)- Drilling Fluid Additive

SERVICE COMPANIES CUT DRILLING FLUID COSTS WITHOUT LOSING PERFORMANCESERVICE COMPANIES CUT DRILLING FLUID COSTS WITHOUT LOSING PERFORMANCE

With industry-wide pressure to reduce expenditures, many service companies have found it cost-effective to reduce the total number of drilling fluid additives by incorporating a premium multi-purpose additive. RAHA Gilsonite provides a range of important benefits while also producing cost savings of more than 80%.

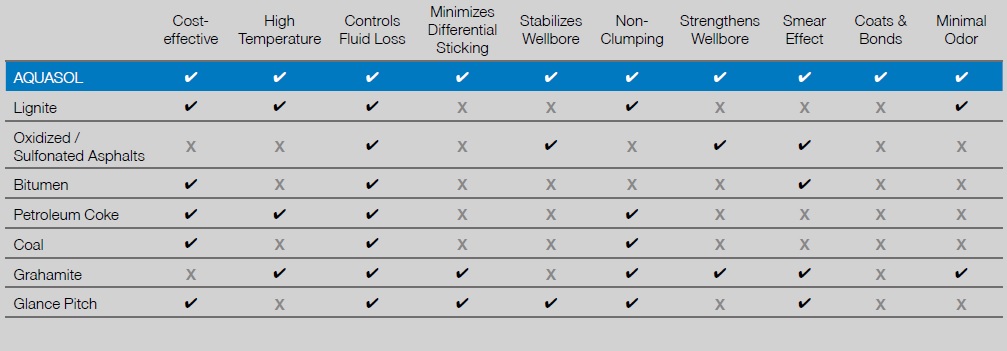

With its unique chemical properties and physical characteristics, Gilsonite is scientifically proven to improve wellbore stability, plug micro-fractures, and bond and seal all types of formations. Gilsonite is the only drilling fluid additive that provides all of these benefits:

- Controls fluid loss

- Stabilizes shales

- Prevents lost circulation

- Strengthens the wellbore

- Minimizes differential sticking

- Performs in oil- and water-based drilling muds

- Performs in HP/HT environments

- Minimizes HSE risks

Fluid Loss Control (FLC) – Proven performance advantages

Laboratory testing and years of field use have proven that Gilsonite offers multiple performance benefits over alternative products.

Fluid Loss Control (FLC) – Unique properties control fluid loss and seepage

Gilsonite has unique bonding and plugging properties that prevent formation damage. Gilsonite forms a physical and chemical bond with permeable formations, creating an effective seal to prevent the passage of drilling fluid. By uniquely functioning as both a malleable and solid plugging agent, Gilsonite controls fluid loss and seepage, prevents lost circulation, and protects reactive and low-reactive shale surfaces, even at elevated bottom hole temperatures.

Fluid loss control (FLC) – Gilsonite prevents lost circulation

Gilsonite has been proven to bond and seals any type of formation. It prevents lost circulation when alone or in combination to enhance the performance of other lost circulation materials (LCM).

Exceptional bonding and plugging properties avoid formation damage

By creating a physical and chemical bond with porous formations, Gilsonite forms an effective seal that inhibits the passage of drilling fluid. Exclusively working as both a ductile and solid plugging agent, Gilsonite controls fluid loss and seepage, avoids lost circulation and protects reactive and low-reactive shale surfaces, even at elevated bottom-hole temperatures.

An established solution for strengthening the wellbore

HP/HT wells, shales, and under pressured zones call for specifically catered drilling fluids and well bore-strengthening practices.

The addition of Gilsonite to an OBM or WBM reinforces the well by:

- Decreasing pore pressure transmission and sealing micro-fractures in shale and low-porosity sands

- Maintaining interbedding formations

- Developing effective filter cake

- Offering a “smear effect” that forms a continuous protective sealant along the wellbore wall

The best additive in avoiding differential sticking

Gilsonite minimizes stuck pipe and stuck logging tool events by meticulously sealing penetrable formations.

- even in zones with a highly overbalanced pressure differential.

- and improving filter cake lubricity.

Functions of Drilling Fluid loss control (FLC)

- Remove cuttings from the well.

- Control formation pressure.

- Suspend and release cuttings.

- Suspend and release cuttings.

- Seal permeable formations.

- Maintain wellbore stability.

- Minimize reservoir damage.

- Cool, lubricate, and support the bit and drilling assembly.

- Transmit hydraulic energy to tools and bit.

- Ensure adequate formation evaluation.

- Control corrosion

- Facilitate cementing and completion.

- Minimize impact on the environment.

- Prevent gas hydrate formation.

Iranian Gilsonite products are good for any application

Fluid loss and shale control. Softening point 350-399°F

Fluid loss and shale control for water-based muds. Softening point 350-399°F

More products are in development, to be launched in the near future.

More than 60 years of oilfield performance success

The success of Gilsonite application as a multipurpose additive has been recognized in almost 50 SPE and other peer-reviewed presentations.

Multifunctional Gilsonite reduces costs

Gilsonite is a premium product that provides value from numerous benefits that improve drilling fluid performance as it also reduces overall costs by requiring fewer additives.

Specification of Gilsonite Drilling Fluid loss control (FLC)

Grade B

| No | Test | Result | Method |

| 1 | Ash Content, wt% | 9-14 | ASTM-D174 |

| 2 | Moisture Content, wt% | <1 | ASTM-D173 |

| 3 | Volatile Matter, wt% | 63 | ASTM-D175 |

| 4 | Fixed Carbon, wt% | 29 | ASTM-D172 |

| 5 | Solubility in CS2,wt% | 89 | ASTM-D4 |

| 6 | Specific Gravity @ 25 Cº | 1,11 | ASTM-D3289 |

| 7 | Color in mass Black | Black | – |

| 8 | Softening Point, Cº | 220 | ASTM-D36 |

| 9 | Flash Point | >420 | Cleveland O.C. |

| 10 | Penetration @ 25 Cº | 0 | ASTM-D5 |

| 11 | Particle Size (mesh) | 200 | Tyler |

Grade A

| No | Test | Result | Method |

| 1 | Ash Content, wt% | 8-10,8 | ASTM-D174 |

| 2 | Moisture Content, wt% | <1 | ASTM-D173 |

| 3 | Volatile Matter, wt% | 69 | ASTM-D175 |

| 4 | Fixed Carbon, wt% | 25 | ASTM-D172 |

| 5 | Solubility in CS2,wt% | 91 | ASTM-D4 |

| 6 | Specific Gravity @ 25 Cº | 0.98 | ASTM-D3289 |

| 7 | Color in mass | Black | – |

| 8 | Softening Point, Cº | 200-220 | ASTM-D36 |

| 9 | Flash Point | >400 | Cleveland O.C. |

| 10 | Penetration @ 25 Cº | 0 | ASTM-D5 |

| 11 | Particle Size (mesh) | >200 | Tyler |