Foundry

General Definition of Gilsonite in Foundry Sands

In Foundry and Refractories, for molding high-value metals there is more attention to factors such as finishing. Gilsonite can be a superior carbon additive replacing the traditional Sea Coal which has low Carbonic value compared to Gilsonite Specifications. Gilsonite is used as a carbonate additive in casting sand to make plates smoother on gray iron molds. Adding Gilsonite makes a better mold that imparts a smoother finish to the cast piece and is easier to remove from the cast item. Gilsonite, in combination with sea coal, is used as special adhesives for casting sand resulting in fewer casting imperfections while improving mold release. Gilsonite is also used as the solidifying agent to shape metals. Gilsonite is used in combination with chemical compounds such as magnesium and hydrated lime for desulfurization practice in the steel industry.

For high-value iron castings, gilsonite performs in foundry sand like no other carbon additive.

Foundries around the world have known for decades that when the fire of molten iron meets foundry sand, Gilsonite makes the difference.

For your complex, high-value iron castings, Gilsonite performs like no other carbon additive. Gilsonite’s naturally superior properties mean high-quality castings with better finish and fewer imperfections.

In terms of quality, high worth iron castings, natural bitumen performs like no alternative carbon additive. natural bitumen is additionally used as an effervescent additive in casting sands that make power tool plates on gray iron castings. In sand case, by adding natural bitumen and asphalts at around one-third the amount of bituminous coal the pitch had an equivalent volatiles. physical sand properties with natural bitumen rosin are equal or superior to bituminous coal at considerably lower additive levels.

Gilsonite can be used in foundry sands as a carbon additive instead of sea coal, which is the conventional item for this application.

The key factor for using Gilsonite as foundry sand additives is the high lustrous carbon content, which also includes a good amount of fixed carbon within. The key matter is adding a secondary layer of graphite while the layer made from Gilsonite carbon prevents the generation of Carbon Monoxide to the Graphite Layer. This procedure is called creating a reductive atmosphere.

While lustrous carbon content, as an important factor in the high-value metal foundry, provides a better finish for molding, the gas generation provided by the Gilsonite is 3 times more than sea coal. This results from an upgraded mold release.

Despite all the advantages, the usage of Gilsonite as a foundry sand additive is decreasing. The reason for this decline is the high price of Gilsonite added to drop of sea coal price in the past years, which caused with the low oil prices, a heavy drop of sales for American Gilsonite Foundry Grade (also GPA Grade) in Europe. Currently, the new origins and resources of Gilsonite are emerging in this market, such as Iranian Gilsonite. Their usage in China & India for foundry sands has been tested successfully. However, the steady market requires more extensive research and greater marketing yet to be done by Iran Gilsonite Suppliers.

compositions of binders and other proprietary materials used to make molds and cores for producing castings are well known. Typical foundry compositions include ingredients such as sodium (western) bentonite, calcium (southern) bentonite, fire clay (kaolinite), sea coal, a highly volatile carbonaceous material such as gilsonite, cereal, cellulose and/or any of the other commonly used foundry sand additives.

Foundry sands, which are composed mainly of silica sand with clays and carbonaceous materials mixed and pulled together when compacted to form molds, resist penetration by molten metal and the tendency of the molding sand to fuse or stick to the casting. One of the problems associated with the known blend carbonaceous additives discussed above, particularly believed due to sea coal, is the smoke and other emissions that can be environmentally hazardous. These gasses are released when the materials are heated in an oxygen-free atmosphere.

Ratio of Gilsonite in Foundry

Although the ratio of one part iron oxide, one part of a highly volatile carbonaceous material such as gilsonite and four parts of metallurgical coke in the additive is a preferred ratio to reduce smoke and/or emissions and give proper finish to the castings, some variations may be permissible. When the additive is combined with the clay, the nominal percentages by weight of the blend would be around 4% iron oxide, 4% gilsonite and 16% metallurgical coke, the balance being essentially 70% to 75% clays and small amounts of other materials.In the case of greater than normal amounts of smoke and/or emissions, the amount of the iron oxide can be increased in steps of 0.5% of the blend with a similar reduction in the metallurgical coke. In the case of poor shakeout peel or casting surface problems, the highly volatile carbonaceous material such as uintaite can be increased in 0.5% steps with a similar reduction in the clay portion of the blend. The permissible ranges of constituents beyond which the additive would be less effective, expressed as a percentage by weight of the blend, are 2%-6% iron oxide, 6%-2% uintaite, and 12%-18% metallurgical coke.

Advantages of Using Gilsonite as an additive in Foundry Sands

- High lustrous carbon for the better finish.

- Reductive atmosphere for less reaction between mold and casting for fewer imperfections

- Significant increase in gas generation comparing to Sea Coal.

- RAHA Gilsonite supply for Foundry application has same lustrous carbon content comparing to the American Gilsonite Foundry Grade while the price is also much closer to sea Coal prices which have dropped with the Oil price drop during the past years.

Packing of foundry gilsonite natural asphalt lump and powder form

Gilsonite in lump form like rock packed in the 500~1000 kg jumbo bag

Gilsonite 200 mesh packed in the 500~1000 kg jumbo bag

Gilsonite 300 mesh packed in the 500~1000 kg jumbo bag

Gilsonite 30-40 mesh packed in the 500~1000 kg jumbo bag

Gilsonite 100 mesh packed in the 500~1000 kg jumbo bag

Gilsonite 300 mesh packed in 25 kg pp bag

Gilsonite 200 mesh packed the 25 kg multi-paper bag

Gilsonite 200 mesh packed the 50 lbs multi-paper bag

Gilsonite 30-40 mesh packed pp bag on the pallet

Bulk on vessel

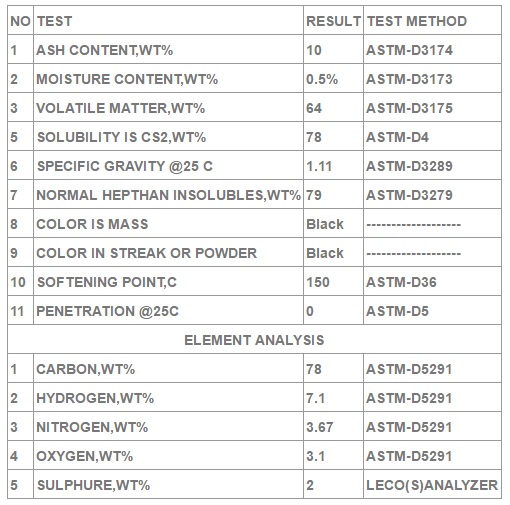

Analysis of Gilsonite Foundry