Drilling Fluids

General description of drilling fluids loss control (FLC)

Gilsonite improves drilling efficiencies, wellbore stability, filter cake development and more.

As an integral component of premium drilling fluid products, Gilsonite actively improves drilling efficiencies while reducing costs and minimizing the HSE impact associated with most drilling fluid additives.

Gilsonite or Natural Asphalt has long been used in oilfields as a fluid loss additive in drilling fluids. In numerous grades and formulations, Gilsonite has been utilized to fight borehole instability complications, offer lubricity particularly in greatly diverged holes, and lately, as a bridging instrument to contest differential pressure sticking and deliver a less invasive coring fluid. It has scientifically proven that suitably framed Gilsonite products can minimalize hole collapse in foundations comprising water-sensitive sloughing shales, and diminish stuck pipe problems by creating a thin wall cake and an inter-matrix filter cake. Gilsonite products are broadly employed worldwide in water based, oil based, and synthetic based mud systems. Furthermore, Blended Gilsonite (Natural Asphalt) is effectively utilized in all water-based systems.

Drilling fluids loss control component appears to be particularly important to fluid loss control as FLC and to act as a shale inhibitor. This loss control by itself would tend to cause an increase in fluid viscosity but this is effectively dealt with by the other components which make up the additive of the invention.

The fluid loss containing filtrate loss control fluids and chemical drilling mud additives, namely, containing filtrate loss control fluids for use in the oil and gas well drilling industry.

As indicated earlier, the additive of the invention comprises the product obtained by reacting together in the presence of water, quebracho, lignite, FLC, sodium sulfite, paraformaldehyde, and sodium hydroxide. Each of the indicated components is essential to obtain optimum results according to the invention.

The reaction conditions used to make the product of the invention can be fairly widely varied. Usually, however, the product is prepared by heating the indicated components in a sealed reaction vessel at a temperature in the order of 100 to 150C. for a period of 120 to 30 minutes, it being appreciated that shorter times can be used as the temperature is increased. It appears that the reaction results in sulphomethylation and causticization of a complex formed between the quebracho, lignite, and asphaltite although the chemistry involved is highly complex and not fully understood. In any case, the resulting composition, which is essentially water-soluble, is preferably dried and may be stored for subsequent blending with conventional clay-based aqueous drilling dispersions or drilling fluids. This blending advantageously is carried out on site although it will be appreciated that the additive may be pre-packed with the drilling fluids.

The invention relates to a composition comprising an HPHT fluid loss control aid, stable at elevated temperatures and which also acts as an excellent shale stabilizer, bore hold lubricant, sealant for depleted sand, and wall cake conditioner. The HPHT fluid loss control aid broadly comprises a Gilsonite (natural asphalt) which also contains a surfactant such as a nonionic surfactant. The HPHT fluid loss control aid also contains a solubilized lignite such as causticized lignite and carbon black. The fluid loss control aid reduces HPHT filtrate loss, has good stability at elevated temperatures such as at 300 °F, stabilizes troublesome shales and decreases borehole erosion, helps seal depleted sands, reduces torque and drag, causes no adverse effects on the flow properties of the properly conditioned drilling fluid, and lowers total well costs.

To achieve these and other advantages, and in accordance with the purpose of the invention, as embodied and broadly described, the invention comprises a composition comprising an HPHT fluid loss control aid stable at elevated temperatures, and which also acts as an excellent shale stabilizer, borehole lubricant sealant for depleted sands, and wall cake conditioner. The HPHT fluid loss control aid broadly comprises Gilsonite, an asphaltic material or solidified hydrocarbon produced by RAHA Gilsonite Company in Iran. The Gilsonite employed according to the present invention also contains a surfactant, especially, a nonionic surfactant.

Gilsonite is the only drilling fluids additive that provides all of these benefits:

- Controls fluid loss and seepage

- Stabilizes shales

- Prevents lost circulation

- Strengthens the wellbore to increase wellbore stability

- Minimizes differential sticking

- Promotes effective filter cake development

- Performs in oil- and water-based drilling muds

- Performs in HP/HT environments

- Minimizes HSE risks

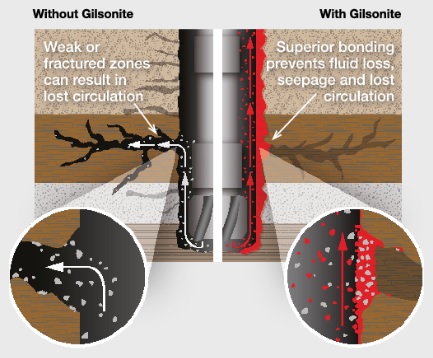

Unique bonding and plugging properties prevent formation damage

Gilsonite forms a physical and chemical bond with permeable formations, creating an effective seal to prevent the passage of drilling fluid. By uniquely functioning as both a malleable and solid plugging agent, Gilsonite controls fluid loss and seepage, prevents lost circulation and protects reactive and low-reactive shale surfaces, even at elevated bottom hole temperatures.

Proven to strengthen the wellbore

HP/HT wells, shales and under pressured zones require specialized drilling fluids and wellbore-strengthening techniques. Adding Gilsonite to an OBM, SBM or WBM strengthens the well by:

- Reducing pore pressure transmission and sealing micro-fractures in shale and low-porosity sands

- Keeping interbedding formations intact

- Developing effective filter cake

- Providing a “smear effect” that creates a continuous protective sealant along the wellbore wall

The most effective additive to prevent differential sticking

Gilsonite minimizes the occurrence of stuck pipe and stuck logging tools by thoroughly sealing permeable formations – even in zones with a highly overbalanced pressure differential – and improving filter cake lubricity.

Health, safety, and environmental advantages

Naturally, occurring Gilsonite has significant health advantages over synthetic products. Gilsonite is:

- Non-toxic (unlike coal or fly ash)

- Non-carcinogenic

- Non-mutagenic

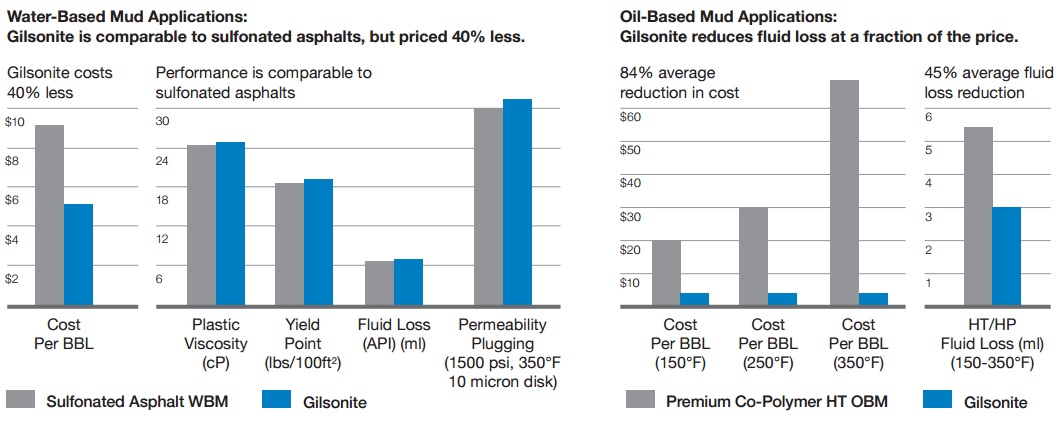

Gilsonite offers significant cost advantages in both OBM and WBM applications

Compared to alternative products, Gilsonite offers comparable or superior performance at a much lower cost. In water-based mud (WBM) applications, Gilsonite’s performance compares favorably with sulfonated asphalts while costing 25-50% less.

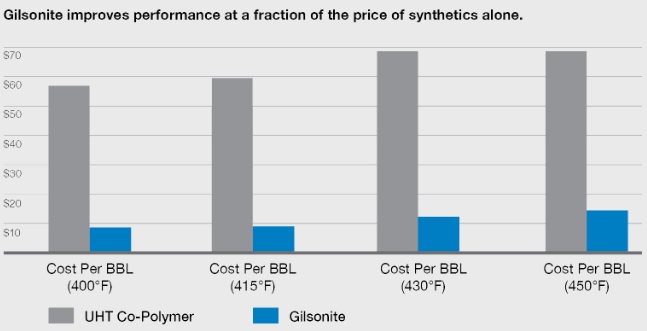

In HP/HT environments using synthetic-based mud (SBM), Gilsonite provides a cost reduction of more than 80% compared to premium co-polymer, while the high softening point of Gilsonite also results in a 45% reduction in fluid loss.

Use of FLC use in fluid loss system

Fluid loss additive has been added to drilling fluids to give better stability of well walls, to lubricate the drill string in a well, to seal microfractures and thus prevent the formation of larger fractures and to decrease the loss of filtrate to formations at high temperatures.

The use of FLC in drilling fluids dispersions or muds, to coat the walls of well holes, is an old and well-established procedure. The purpose of the fluid is to stabilize the walls of the hole by forming a relatively thin but strongly adherent coating or cake on the walls. The coating must be able to withstand relatively high temperatures and it should be resistant to the passage of moisture or fluid therethrough.

Packing of drilling fluids loss control lump and powder form

FLC in lump form like rock packed in 500~1000 kg jumbo bag

FLC 200 mesh packed in 500~1000 kg jumbo bag

Drilling fluid additive 300 mesh packed in 500~1000 kg jumbo bag

Drilling fluid additive 30-40 mesh packed in 500~1000 kg jumbo bag

Drilling fluid additive 100 mesh packed in 500~1000 kg jumbo bag

Drilling fluid additive 300 mesh packed in 25 kg pp bag

Drilling fluid additive 200 mesh packed 25 kg multi-paper bag

Drilling fluid additive 200 mesh packed 50 lbs multi-paper bag

Drilling fluid additive 30-40 mesh packed pp bag on pallet

Bulk on vessel

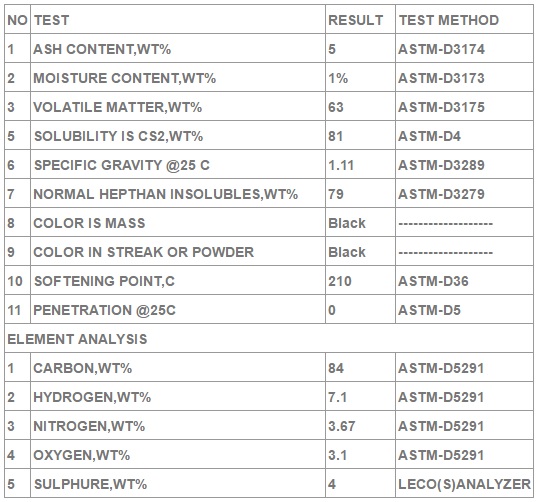

Analysis of drilling fluid loss control