PAC HV easily disperses in all water-base drilling fluids and applicable from fresh water to saturated salt water drilling fluids.

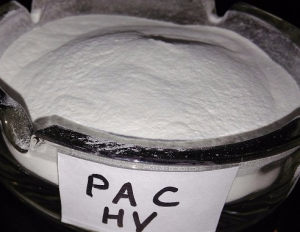

What is PAC HV Bentonite?

The drilling and completion fluid technique is an important part of oil drilling project and plays a critical role in ensuring safe, high-quality and fast drilling. As a kind of treating agent to improve the drilling and completion fluid performance, the cellulose ether has an important role in reducing fluid loss and increasing viscosity.

PAC HV can improve the coagulation stability of the system by forming a relatively thick solvent absorption layer on the particle surface of drilling fluids, reduce the electrostatic attraction between particles by absorbing fine particles of clay and thus increasing the surface charge of particles, and the permeability of filter cake by enhancing the viscosity and capability to plug holes of filtrate

PAC HV easily disperses in all water-base drilling fluids and applicable from fresh water to saturated salt water drilling fluids. In low-solid and solid-free drilling fluids, PAC HV can strikingly reduce the filter loss as well as the filter cake thickness, and shows strong inhibitory effects on the shale hydration.

Introduction to Drilling Fluid Technologies

Drilling fluid technology is constantly evolving due to increasing demands in severe conditions, technical demands, and restrictions on oil-based systems. To comply with government regulations, drilling fluid manufacturers have developed acceptable alternatives, but these often have significant costs and limitations.

To address these issues, drilling fluid development should focus on designing environmentally acceptable water-based (WBM) and oil-like systems that provide alternatives to oil-based (OBM). These fluids should provide superior filtration control, prevent fluid invasion, and provide adequate hole cleaning capabilities, especially in horizontal or high-angle wells.

The study of cuttings transport flow, air foam behavior, and fluid viscoelastic behavior can help improve this process. To achieve greater efficiencies and cost savings, R&D programs should focus on developing environmentally-benign drilling fluids, designing non-toxic drilling fluids and foams as alternatives to toxic OBM, which are difficult to remove from the drill hole.

The Importance of Drilling Fluids in Wellbore Stability

Wellbore Stability is one of the primary functions of drilling fluid. They help to maintain wellbore stability by providing hydrostatic pressure to counteract the natural pressure of the formations being drilled. The fluid acts as a barrier between the drilling fluid and the surrounding rock formations, preventing caving and other geological issues that could cause damage to the wellbore. This stability is particularly important when drilling in deep and unstable geological formations. Drilling fluid also acts as a lubricant, reducing the friction and heat generated by the drilling process, which can cause formation damage and reduce the efficiency of the drilling operation.

One of the primary ways in which drilling fluids help maintain wellbore stability is by exerting hydrostatic pressure on the formation being drilled. This pressure helps to prevent the formation from collapsing or caving in, which can lead to well control issues, lost circulation, and other problems. The weight of the drilling fluid is carefully calculated to ensure that it is sufficient to counteract the natural pressure of the formation being drilled.

Another way in which drilling fluids help to maintain wellbore stability is by forming a filter cake on the wellbore walls. This filter cake helps to prevent the drilling fluid from invading the formation and causing damage. The filter cake is formed by the solids in the drilling fluid, which are deposited on the wellbore walls as the fluid circulates. The thickness and composition of the filter cake can be adjusted to suit the specific needs of the formation being drilled.

Application

Oil and Gas Industry

High Viscosity Polyanionic Cellulose (PAC HV) market, the oil and gas sector stand out as a major application area. PAC HV is extensively utilized in drilling fluids due to its high viscosity and excellent suspension properties. The substance helps in maintaining wellbore stability and enhancing the efficiency of drilling operations by controlling fluid loss and reducing friction. This is particularly crucial in challenging drilling environments, where high performance is required to manage the complex interactions between the drilling fluid and the rock formations.

The demand for PAC HV in this sector is driven by the ongoing exploration and production activities, which continuously seek advanced materials to optimize drilling performance and ensure operational safety. As the industry evolves and new reserves are tapped, the need for high-quality PAC HV products remains integral to the success of drilling projects.

Construction and Building Materials

In the construction sector, High Viscosity Polyanionic Cellulose (PAC HV) is valued for its role in enhancing the properties of cement-based and gypsum-based building materials. PAC HV is incorporated into formulations to improve workability, consistency, and water retention in materials such as mortars, plasters, and concrete. Its high viscosity helps in achieving a smoother texture and more efficient application, making it easier to work with and more effective in achieving desired finishes.

The demand for PAC HV in construction applications is fueled by ongoing infrastructure development and renovation projects, which require reliable and high-performance materials. As building standards and regulations become more stringent, the use of PAC HV is expected to rise, driven by the need for durable and high-quality construction solutions.

Pharmaceutical and Personal Care Products

In the pharmaceutical and personal care industries, High Viscosity Polyanionic Cellulose (PAC HV) is utilized for its gelling and thickening properties. It is commonly found in a range of products including gels, creams, and ointments, where it contributes to the desired texture and stability.

PAC HV is favored for its ability to form stable, non-Newtonian fluids, which are essential for maintaining consistent product performance and efficacy. The growing demand for advanced personal care and pharmaceutical formulations drives the need for high-quality PAC HV, as manufacturers seek to enhance product formulations and ensure consumer satisfaction. As these industries continue to innovate and expand, the role of PAC HV in creating effective and appealing products is expected to become increasingly significant.

The Synergy Between PAC HV and Bentonite

The synergy between PAC HV and bentonite is a complex and fascinating interaction that has significant implications in various fields, particularly in environmental remediation and water treatment. Both PAC HV and bentonite are highly effective materials in their own right, but when combined, they can exhibit enhanced properties and performance.

Synergistic Effects

When PAC HV and bentonite are combined, several synergistic effects can occur:

Enhanced Adsorption: The combination of PAC HV and bentonite can lead to a significant increase in adsorption capacity compared to either material alone. This is due to the interaction between the porous structure of Polyanionic Cellulose High Viscosity and the swelling properties of bentonite. The bentonite can create a favorable environment for the adsorption of contaminants onto the surface of the PAC HV.

Improved Filtration: Bentonite can act as a filter aid, enhancing the filtration efficiency of PAC HV. The swelling of bentonite can create a more porous and open structure, allowing for better filtration of suspended solids and contaminants.

Enhanced Rheological Properties: The addition of bentonite to PAC HV can improve its rheological properties, making it easier to handle and apply. Bentonite can provide a more stable suspension and prevent settling.

Reduced Contaminant Release: The combination of Polyanionic Cellulose High Viscosity and bentonite can help to reduce the release of contaminants from the adsorption process. Bentonite can act as a barrier, preventing the desorption of adsorbed contaminants.

Drilling mud containing polyanionic cellulose

can form thin and sturdy wellbore walls and low-permeability filter cakes, thereby reducing the phenomenon of hole shrinkage and collapse caused by mud loss.

Mud that contains added PAC is rarely affected by molds, so it does not need to maintain a high pH or use a preservative. It can remain stable even with a certain range of temperature changes during drilling, as the amount of other chemical agents used in it is correspondingly reduced.

Drilling mud with PAC has a lower initial gel strength, making it easier to remove air and debris from the mud pit. PAC-HV is suitable for low-density and small-quantity mud and can increase viscosity and reduce filtration. A small amount of PAC can replace a large amount of clay. This type of mud can reduce the difficulties encountered during drilling CaSO42H20 or CaSO4 salt. However, PAC-LV is suitable for high-density mud, can reduce filtration but has little effect on viscosity. When using it, dissolve PAC in water to create a solution (generally 1/40-1/20), and then add it to the mud. PAC can also be compounded with other chemical agents and added to the mud.

Advantages

- Easy to mix through hopper

- Compatible with most types of regular water-based muds

- Stable up to 250° F

- Provide excellent filtration control

- Improve rheological properties

- Environmentally acceptable

- Effective in wide range of pH

PAC HV vs. PAC LV

PAC HV (High Viscosity) and PAC LV (Low Viscosity) are both types of Polyaluminum Chloride (PAC), a coagulant commonly used in water treatment processes. The primary difference between them lies in their viscosity.

Viscosity

PAC HV: As the name suggests, PAC HV has a higher viscosity than PAC LV. This higher viscosity can be beneficial in certain applications, such as when dealing with high turbidity or when needing a slower settling rate.

PAC LV: PAC LV, on the other hand, has a lower viscosity. This can be advantageous in situations where rapid flocculation and sedimentation are desired.

Applications

PAC HV: Often used in:

- Wastewater treatment

- Potable water treatment

- Industrial water treatment (e.g., paper mills, textile plants)

PAC LV: Frequently used in:

- Drinking water treatment

- Industrial water treatment (e.g., food processing)

Key Considerations

Turbidity: For higher turbidity water, PAC HV might be more effective due to its higher viscosity, which can bridge larger particles.

Sedimentation Rate: If a slower sedimentation rate is desired, PAC HV can be considered.

Mixing: PAC HV may require more intense mixing due to its higher viscosity.

Dosage: The optimal dosage of PAC HV or PAC LV will depend on the specific water quality and treatment goals.

Physical Properties

| Parameter | Specifications |

|---|---|

| Appearance | Off white to Creamish free flowing powder |

| Nature of Polymer | Poly Anionic Cellulose |

| Moisture Content | Max. 10% |

| PH of 1% Solution | 8.0 – 10.0 |

| Solubility | Soluble in fresh water |

| Apparent Viscosity | 50 cps min |

| Filtrate Volume | 23 ml max |